Micro-D

Omnetics offers reliable Micro-D connectors in standard, latching, single row, MIL-DTL-83513, and USB 3.0 configurations.

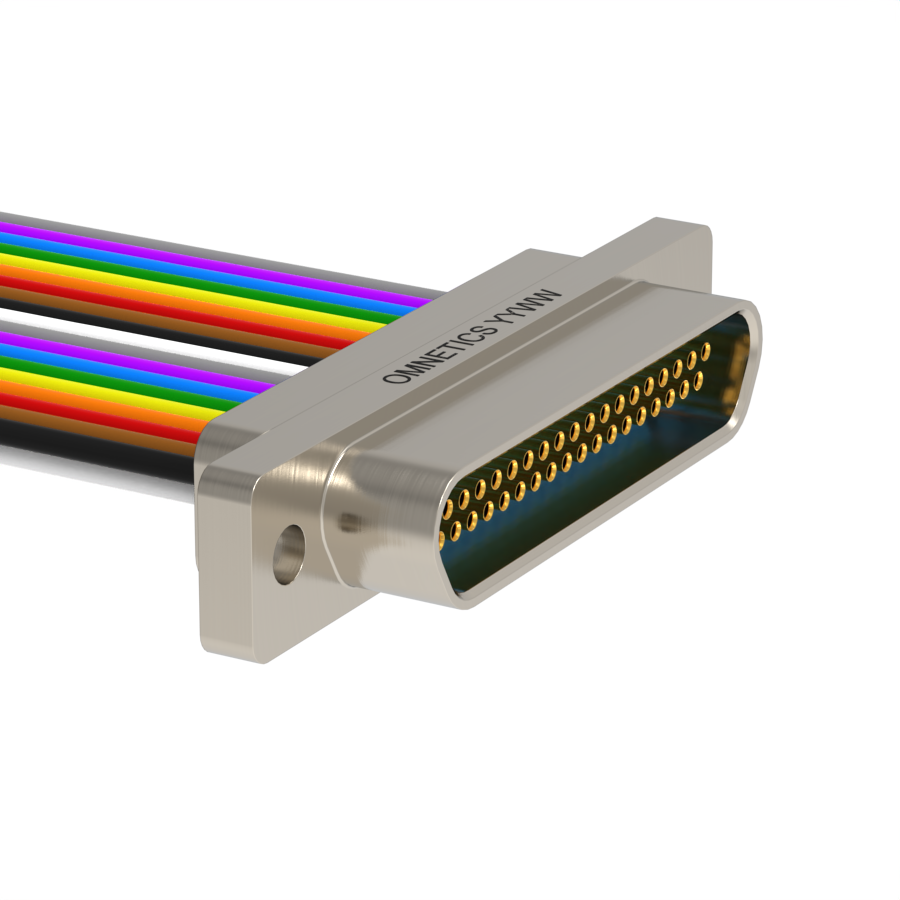

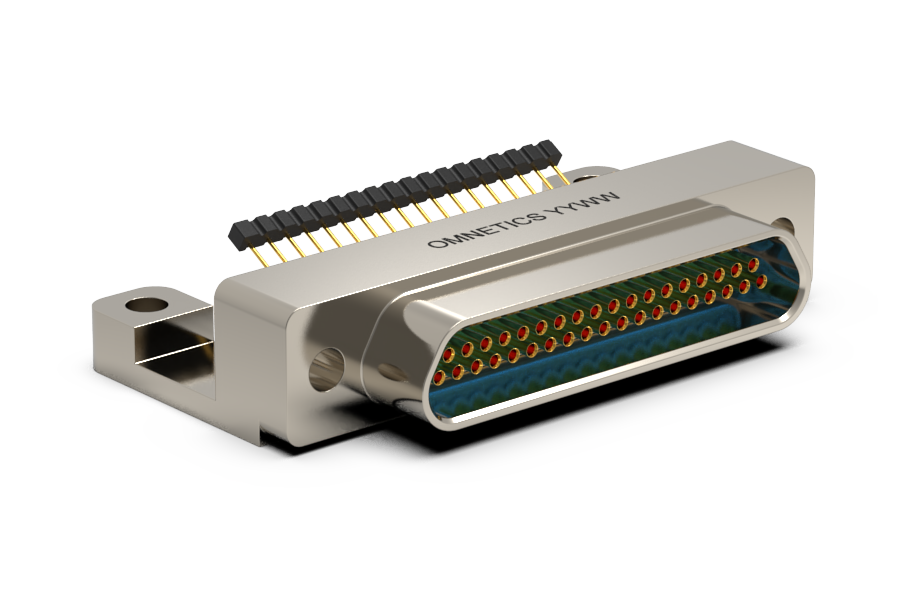

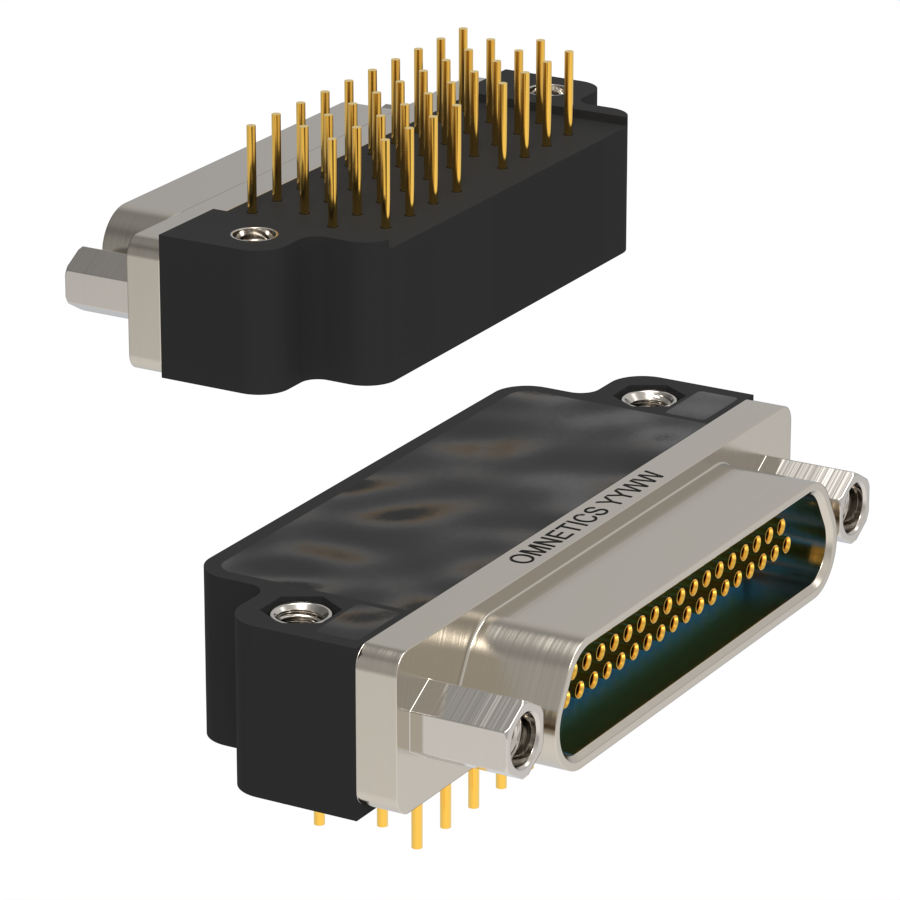

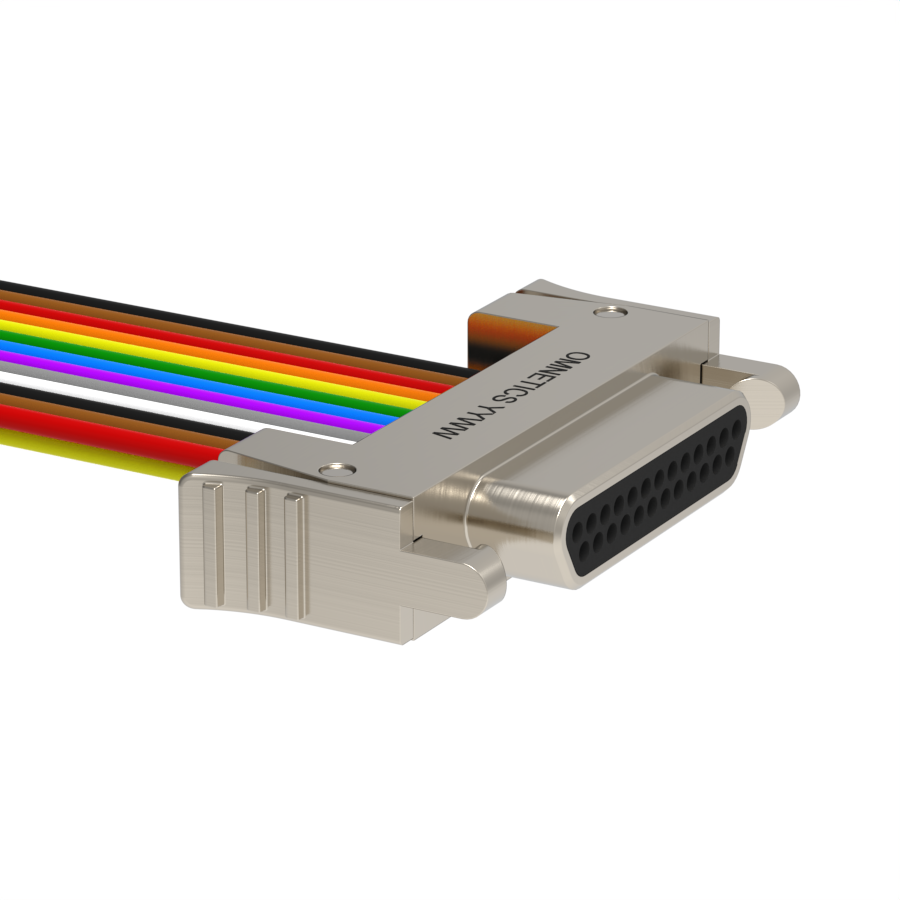

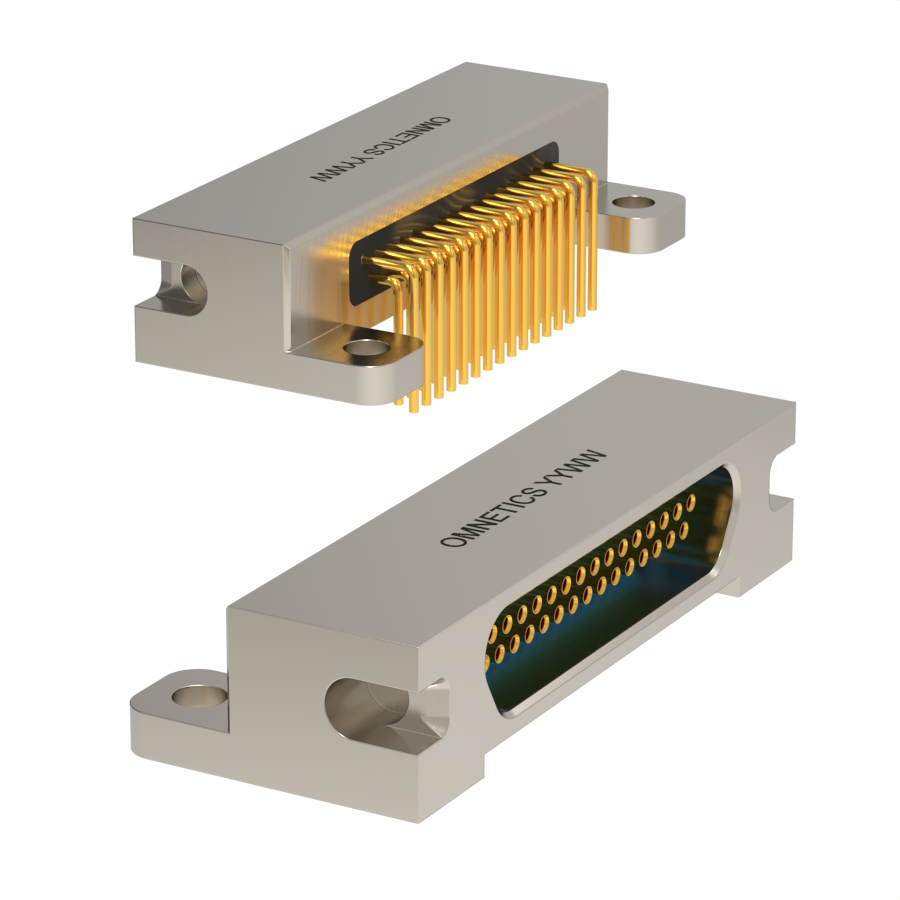

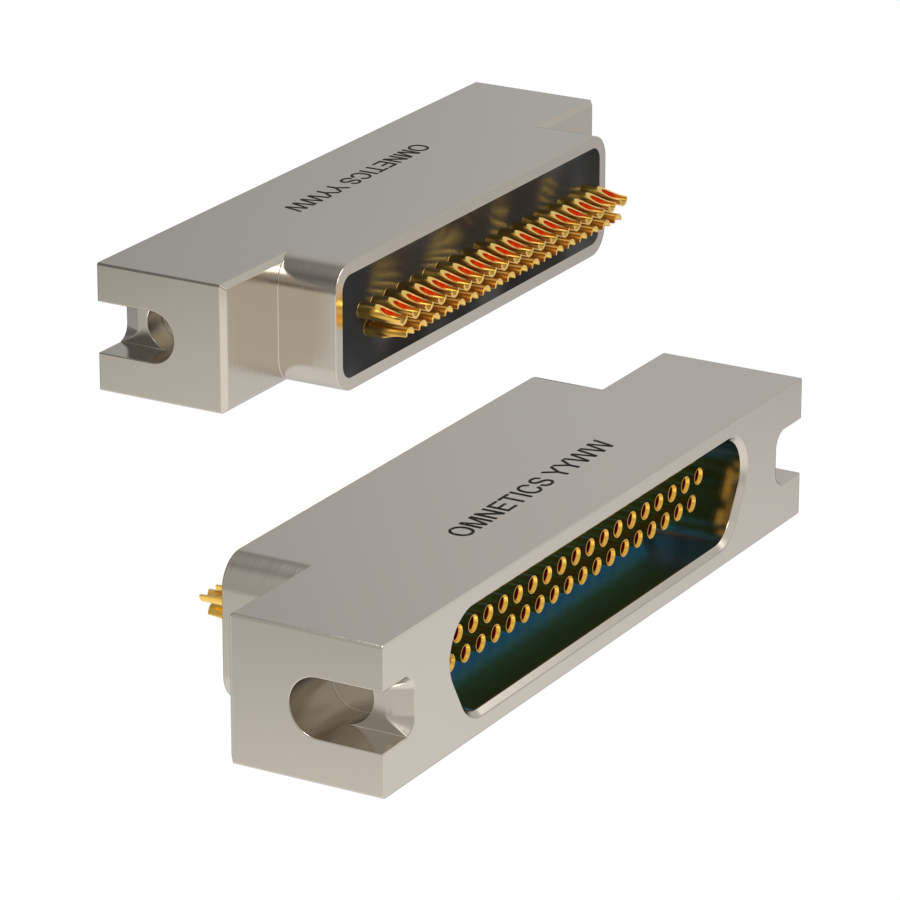

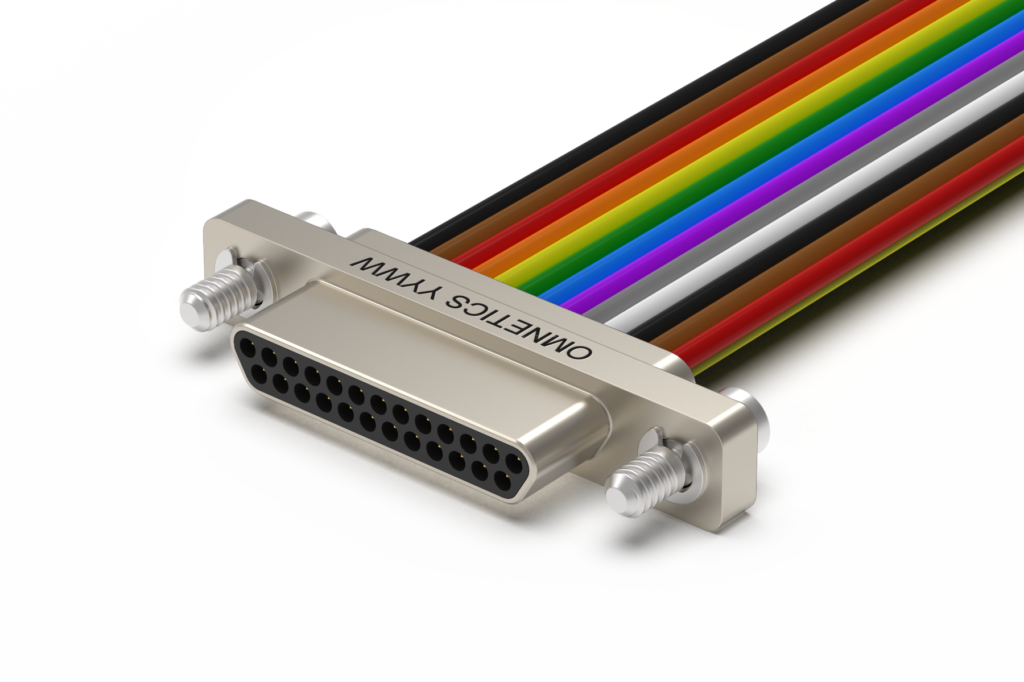

Standard Micro-D Connectors

Omnetics Micro-D subminiature connectors are QPL qualified and designed and manufactured to meet and exceed MIL-DTL-83513. The connector assembly is built to assure the highest performance through high shock and vibration applications as well as extreme environmental use. They use the proven beryllium copper spring pin to socket contact system plated with both nickel and gold that assures the highest quality for mating and de-mating and very low contact resistance. Pin and sockets are set at .050” center to center lines. Our standard and COTs models are available in pin counts from 9 through 51 positions and come available in solder cup and wired as well as board mount configurations. The collection of Micro-D connectors also includes special high temperature versions, deep space versions with NASA qualified low outgassing, as well as mixed signal designs fabricated to match your application directly.

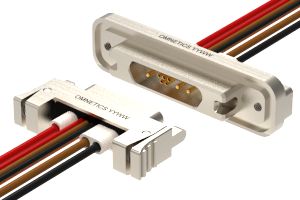

Latching Micro-D Connectors

Omnetics’ high-reliability Latching Micro-D connectors offer the same rugged performance as a standard Micro-D connector while eliminating the need for threaded hardware (jackscrews) and tools with the Quick Latching connector system. These Latching Micro-D connectors are ideal for applications requiring secure micro-miniature connectors.

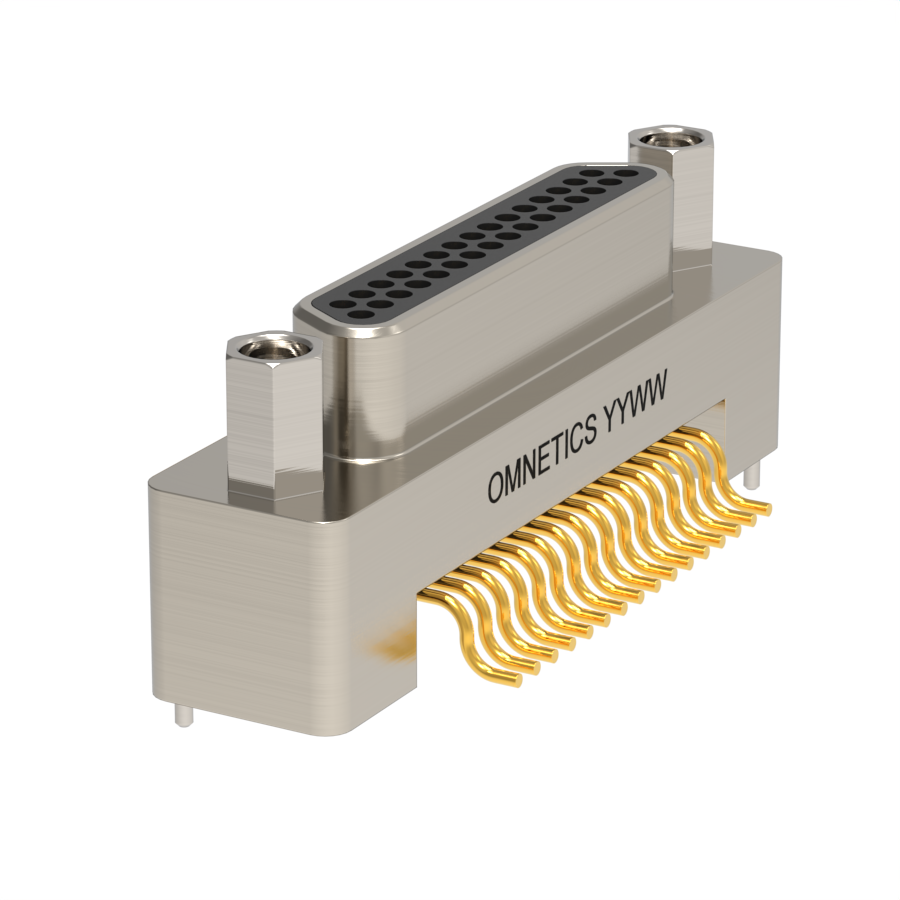

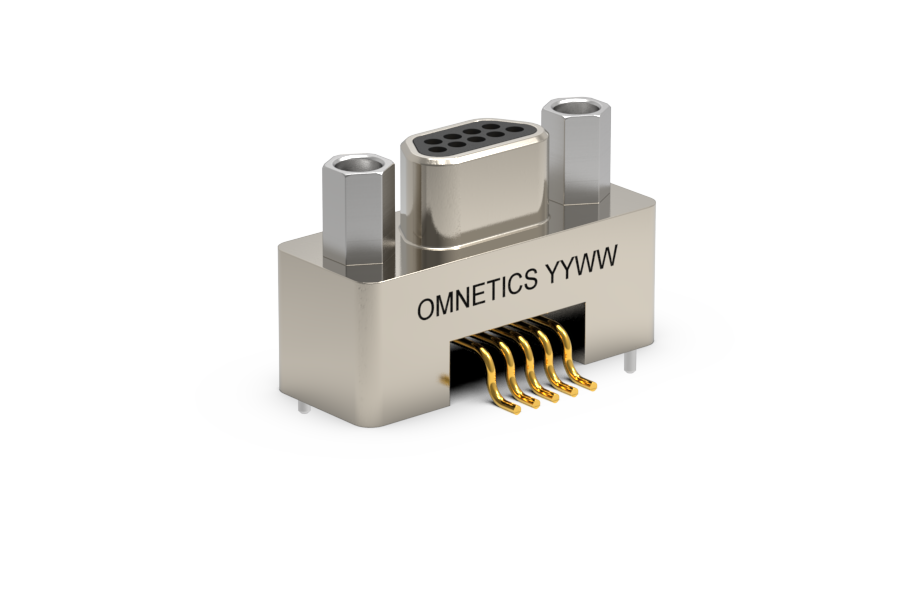

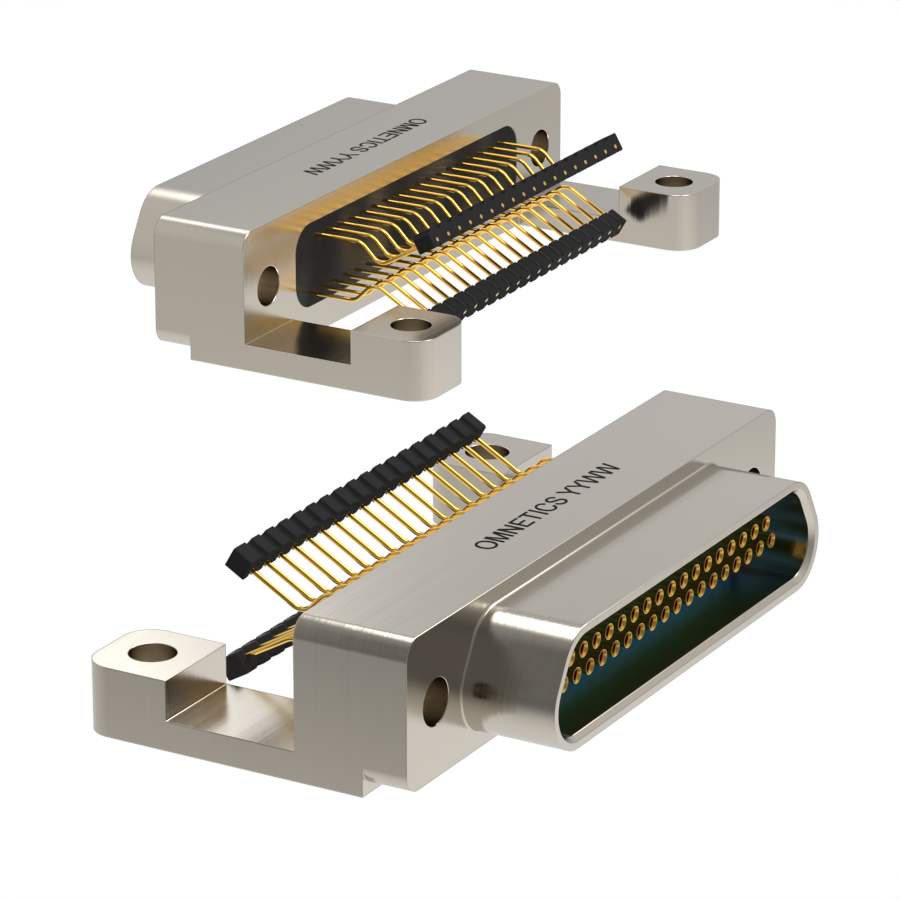

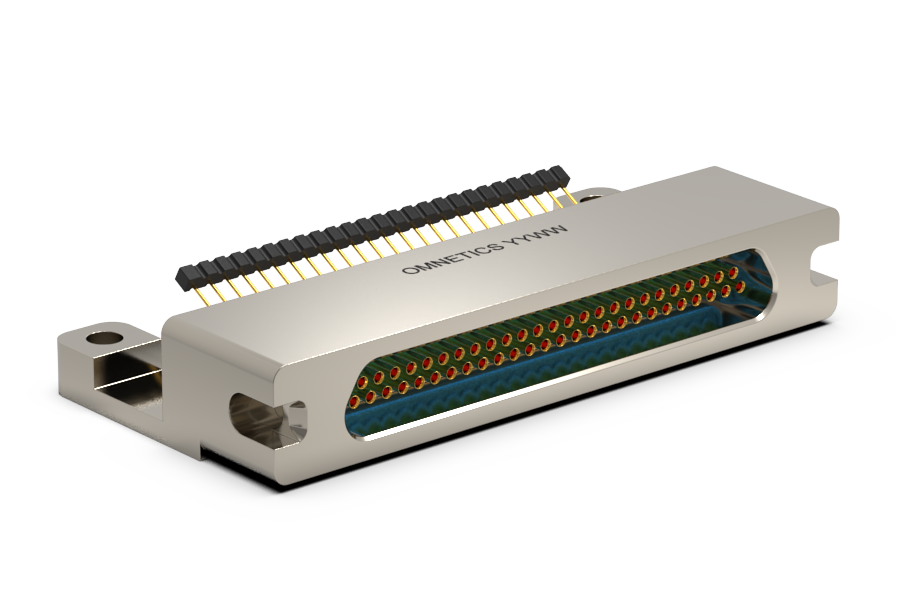

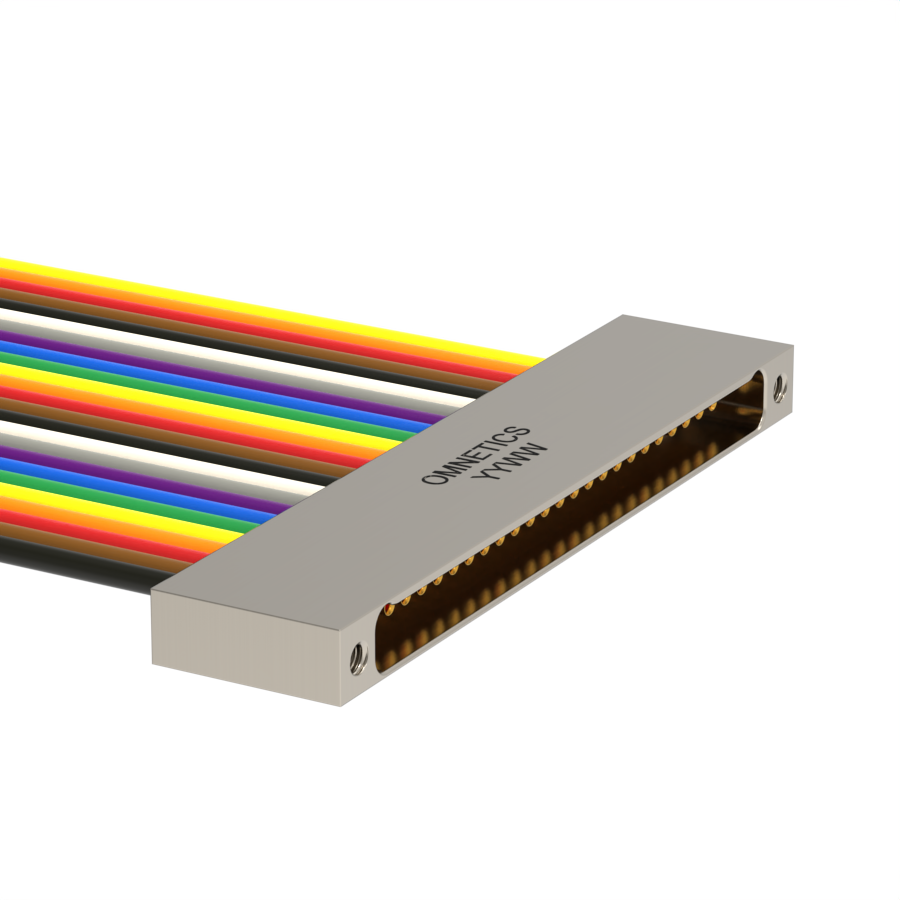

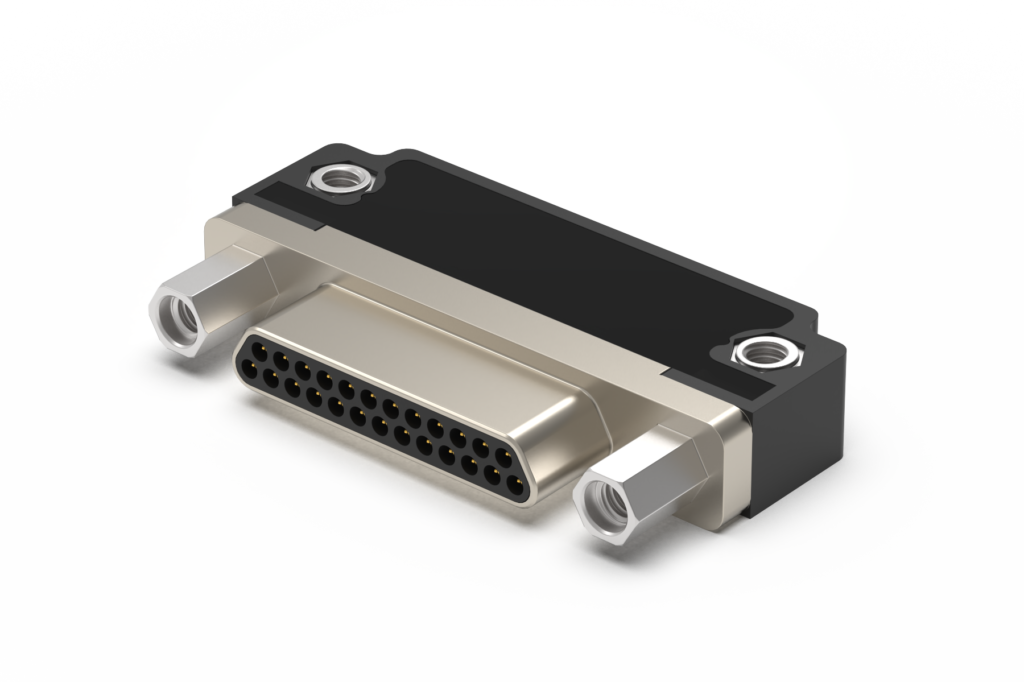

Single Row Micro-D Connectors

The single row Low Profile Micro-D microminiature connectors are ideal for critical, high reliability miniaturized electronic modules. These Low Profile Micro-D connectors occupy less space than comparable two row Micro-D connectors.

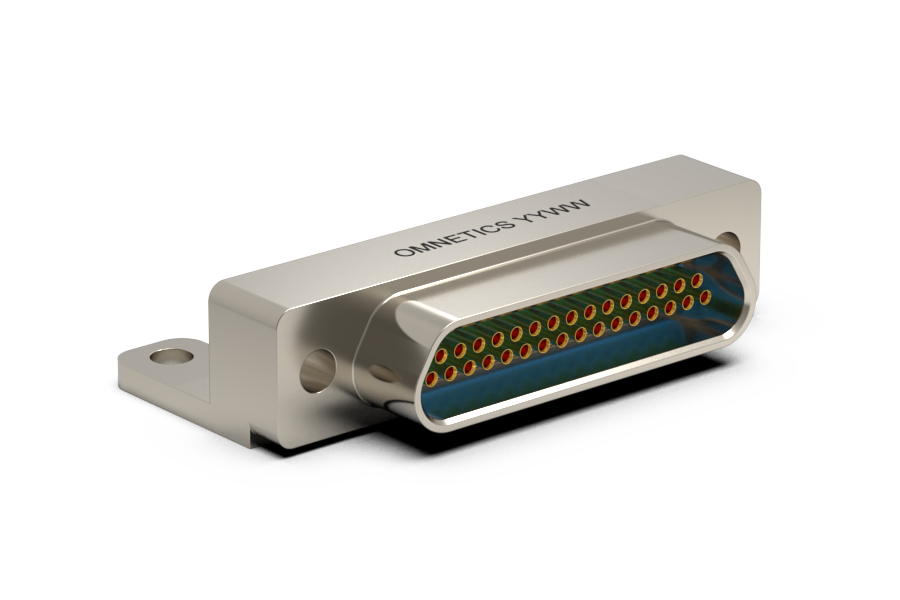

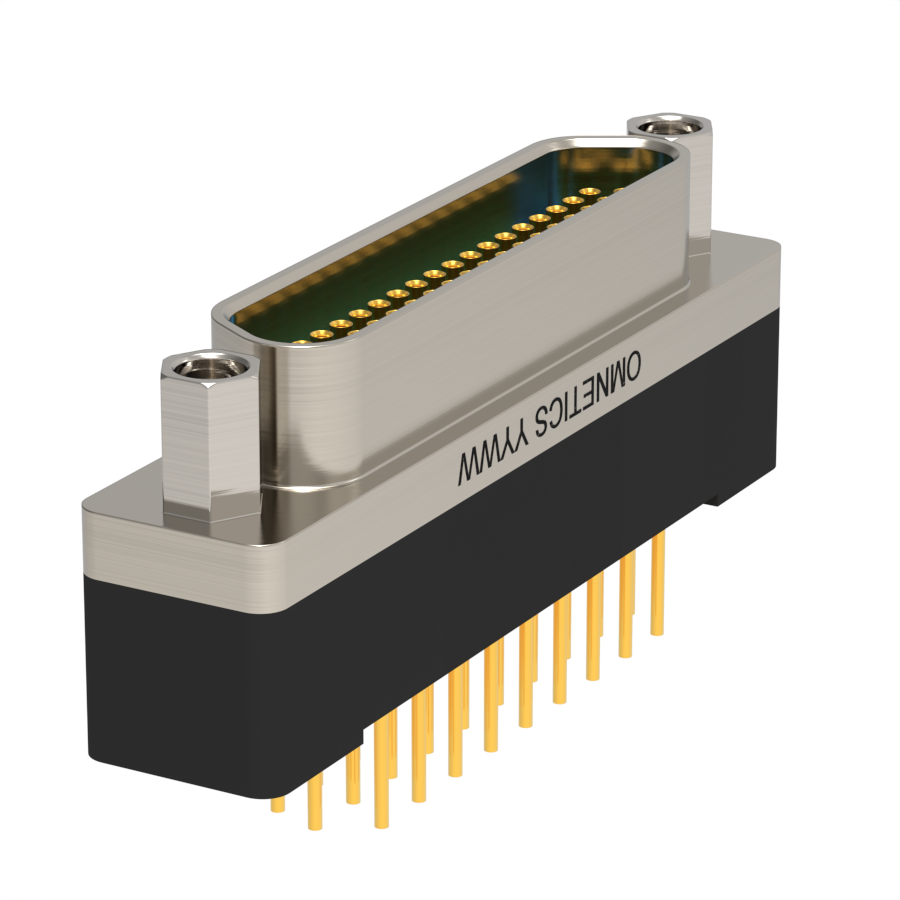

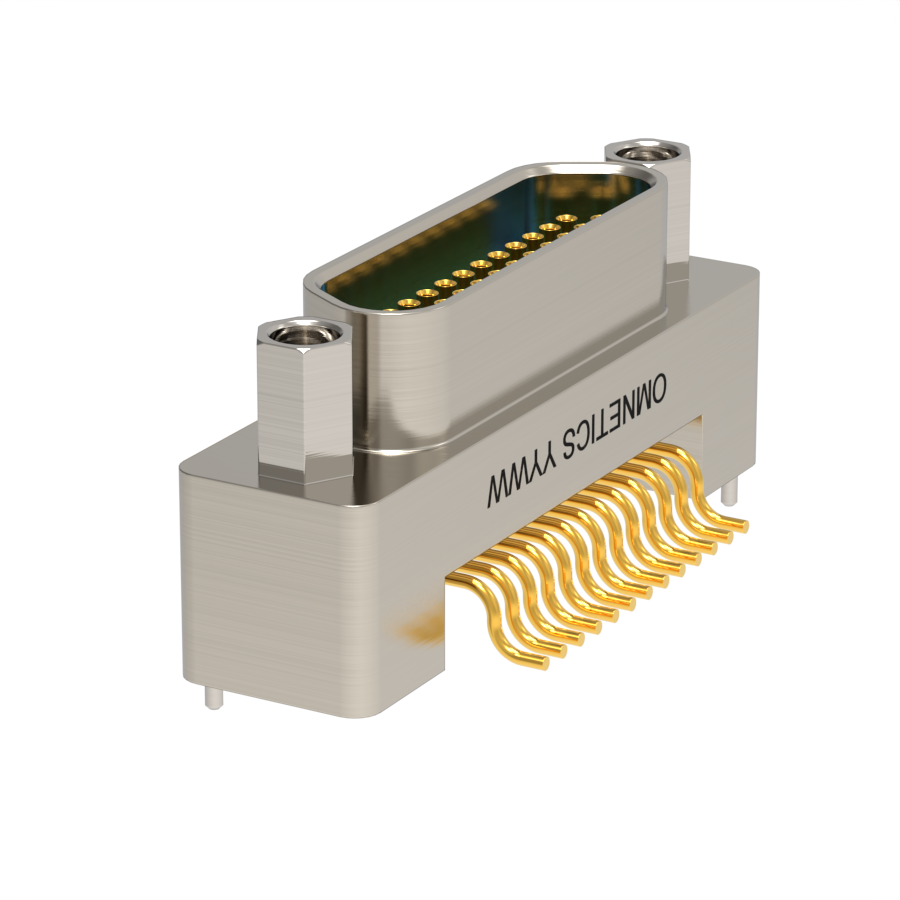

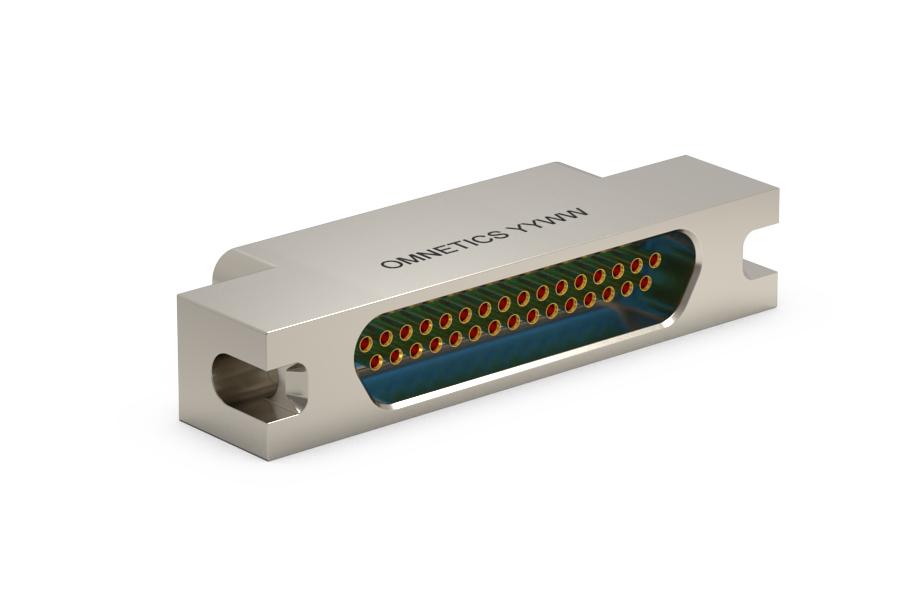

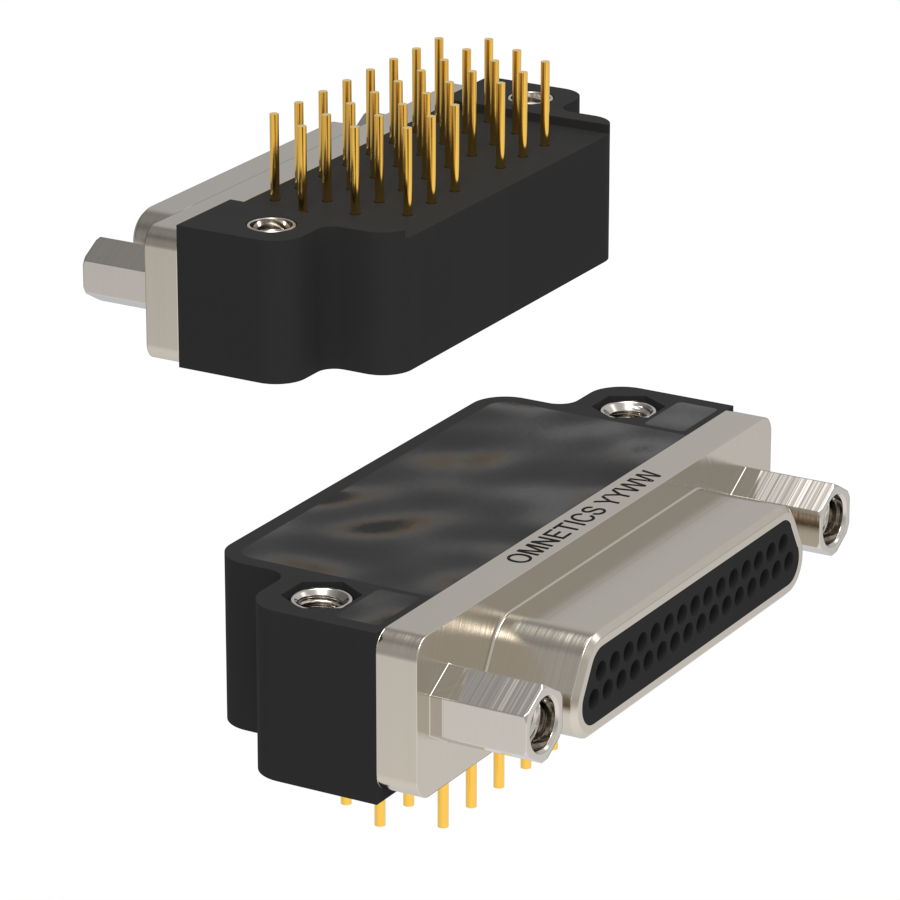

Low Profile Micro-D Connectors

The Low Profile Micro-D connector series offers proven military specification performance and reliability with reduced flange height and weight compared to standard Micro-D connectors. These micro miniature Low Profile Micro-D connectors are used in military, aerospace, petroleum, and medical applications.

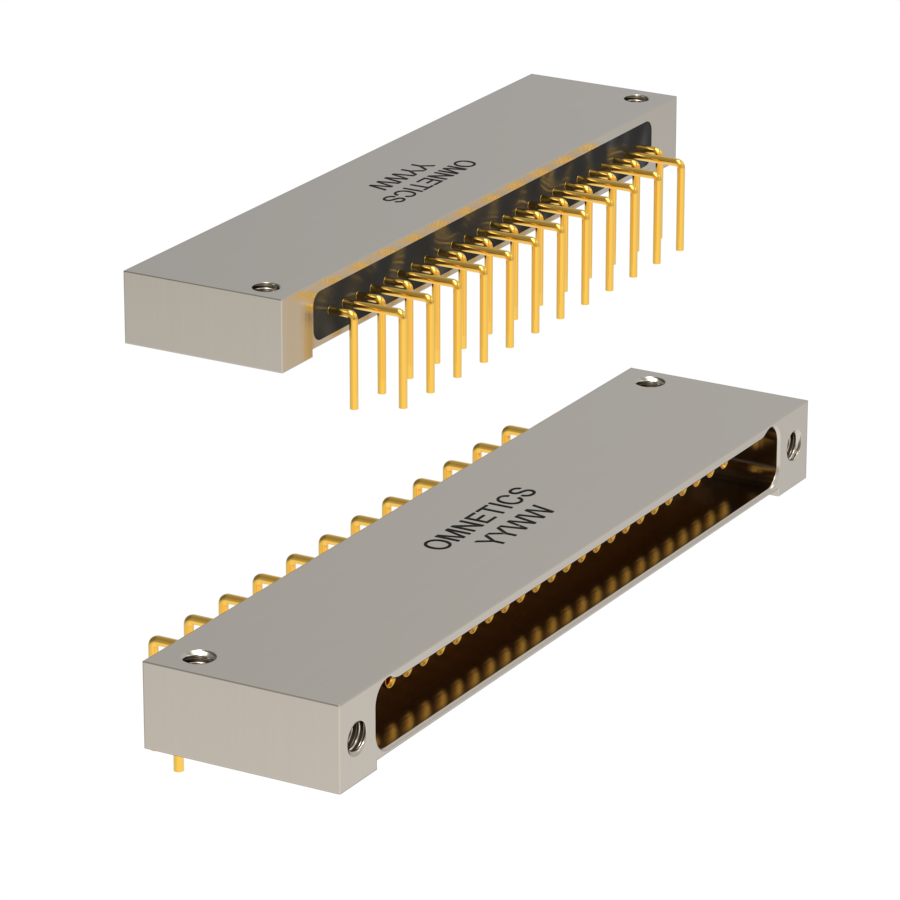

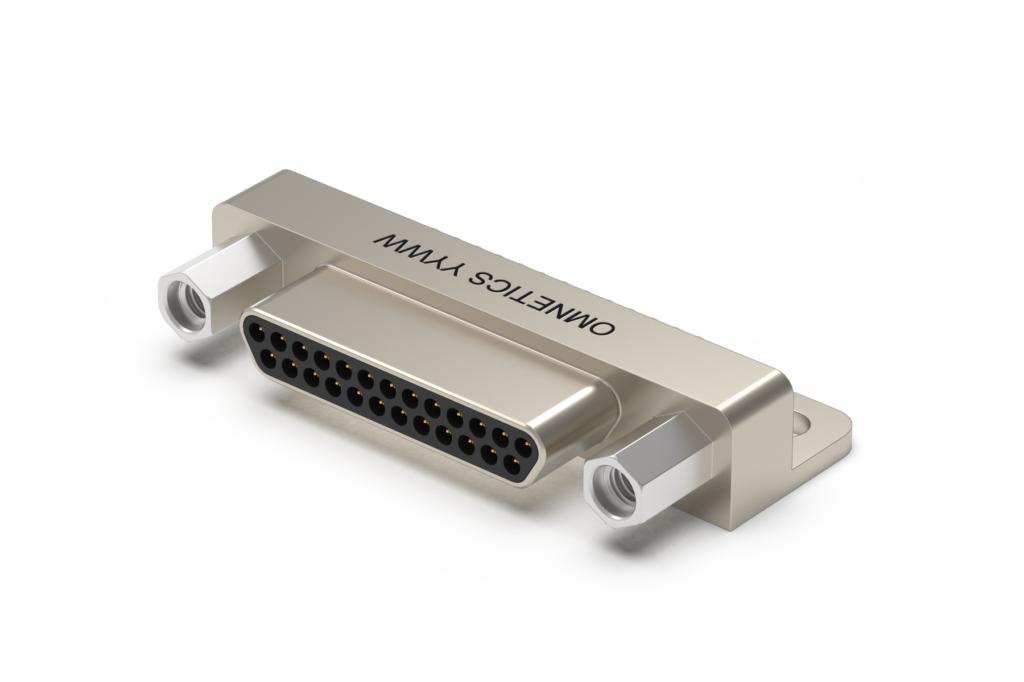

MIL-DTL-83513 Connectors

MIL-DTL-83513 qualified Micro-D connectors.

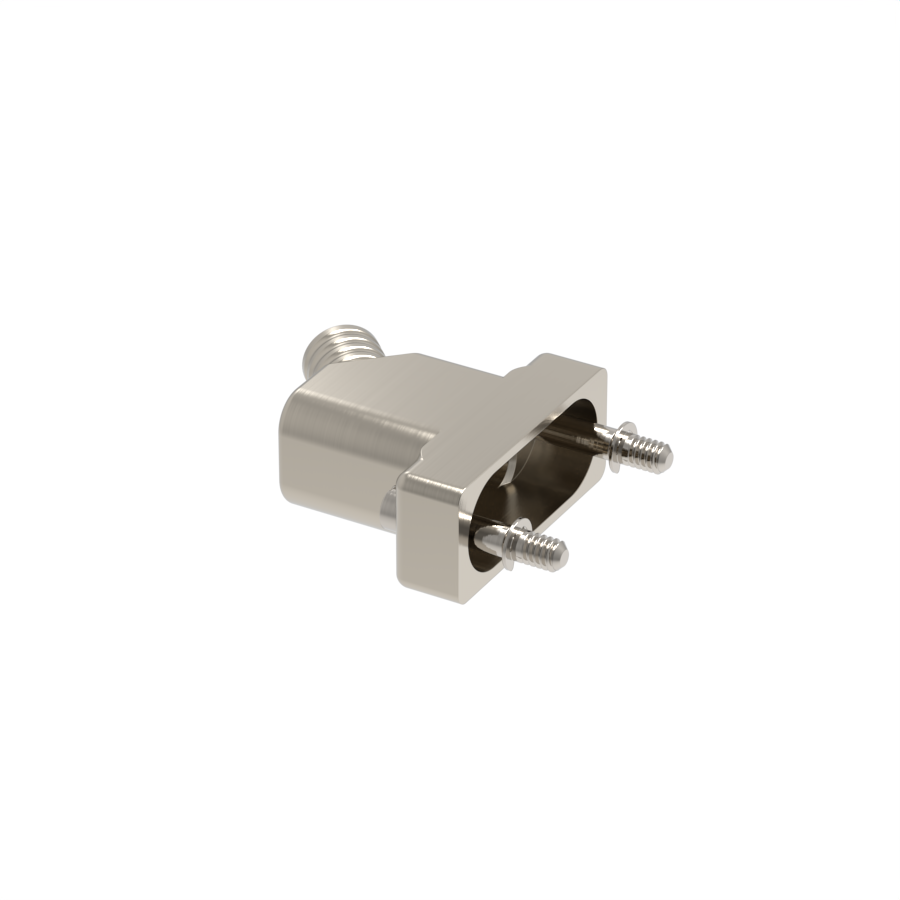

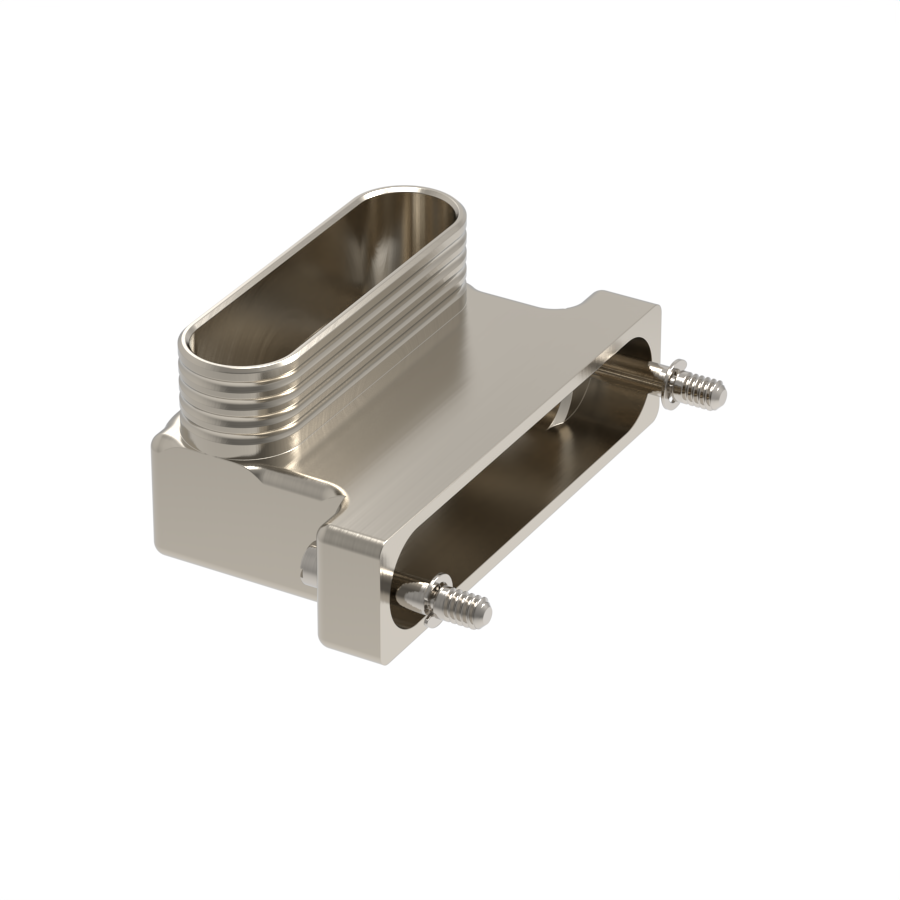

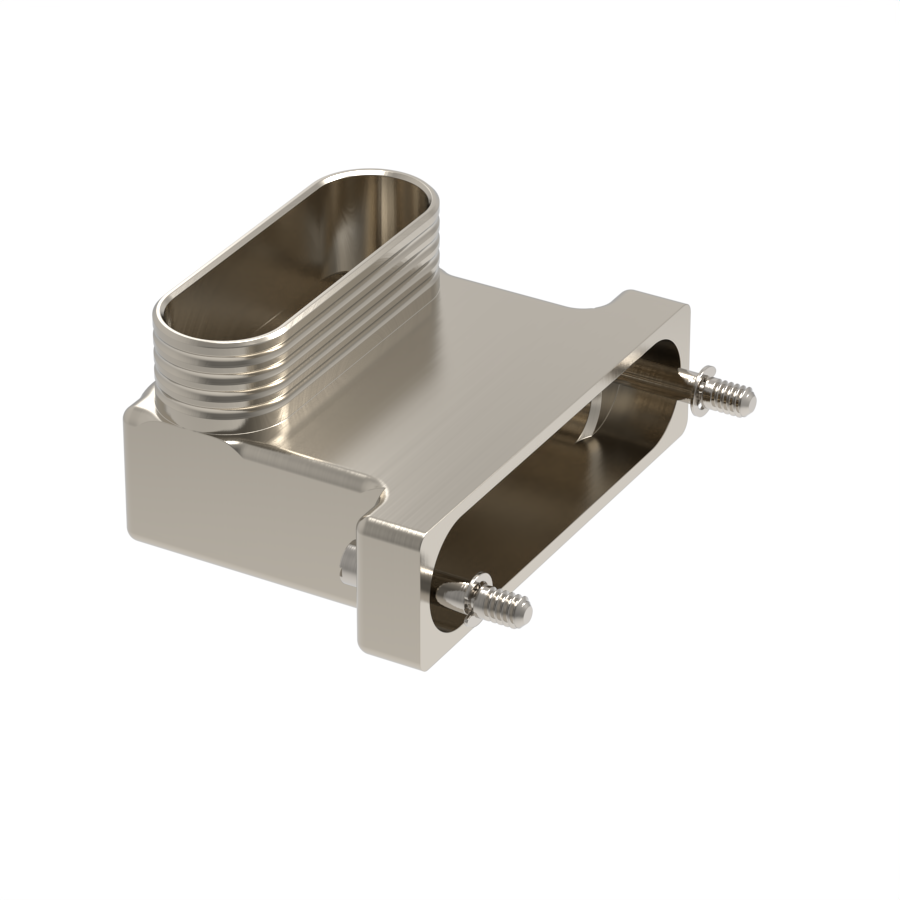

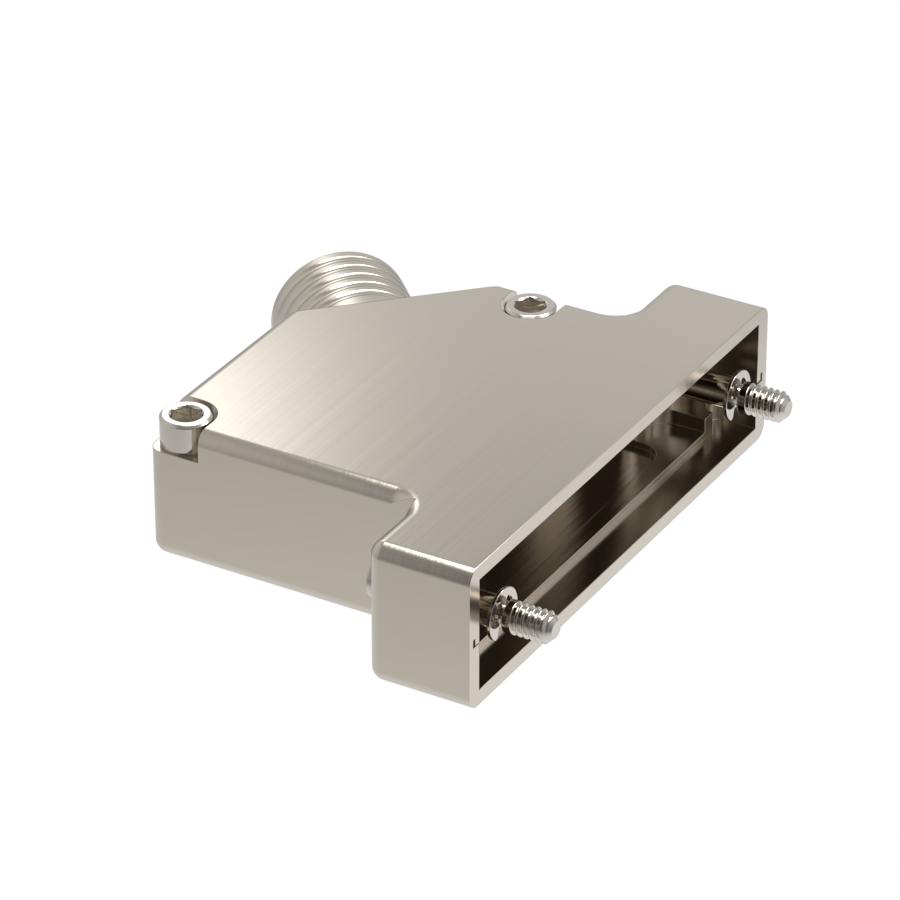

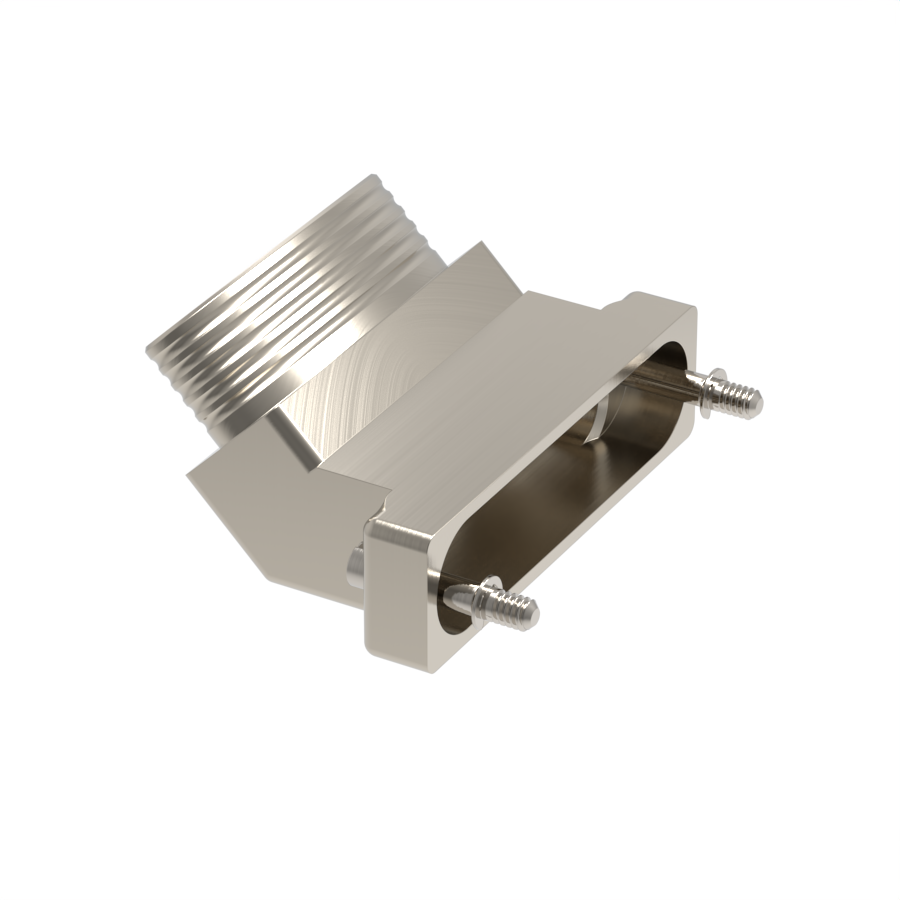

Micro-D Backshell Options

Omnetics Micro-D backshells provide EMI protection, strain relief and mechanical protection. These backsehells are compatible with industry-standard metal MIL-DTL-83513 type connectors.