Signal Integrity R&D and Support

As signal data

rates continue to rise, connector manufacturers must continually evaluate their

manufacturing processes and product offerings to ensure they continue to

provide reliable products while meeting the market demands. High reliability

connectors will always be a cornerstone for Omnetics, but for many

applications, a robust mechanical design must be balanced with a solution that

is also optimized for high-speed. In order to achieve this, many aspects of the

design – material selection, connector spacing, termination strategy, and

cabling – must be constantly under evaluation. Omnetics uses a combination of

software and hardware to address these challenges.

For design

optimization, Omnetics uses ANSYS HFSS, a 3D Electromagnetics simulation tool,

to simulate and optimize the performance of their products. This allows Omnetics to quantify the impact

of various design options prior to manufacturing, helping to constantly improve

products and find ways to maximize the data rates of any given solution.

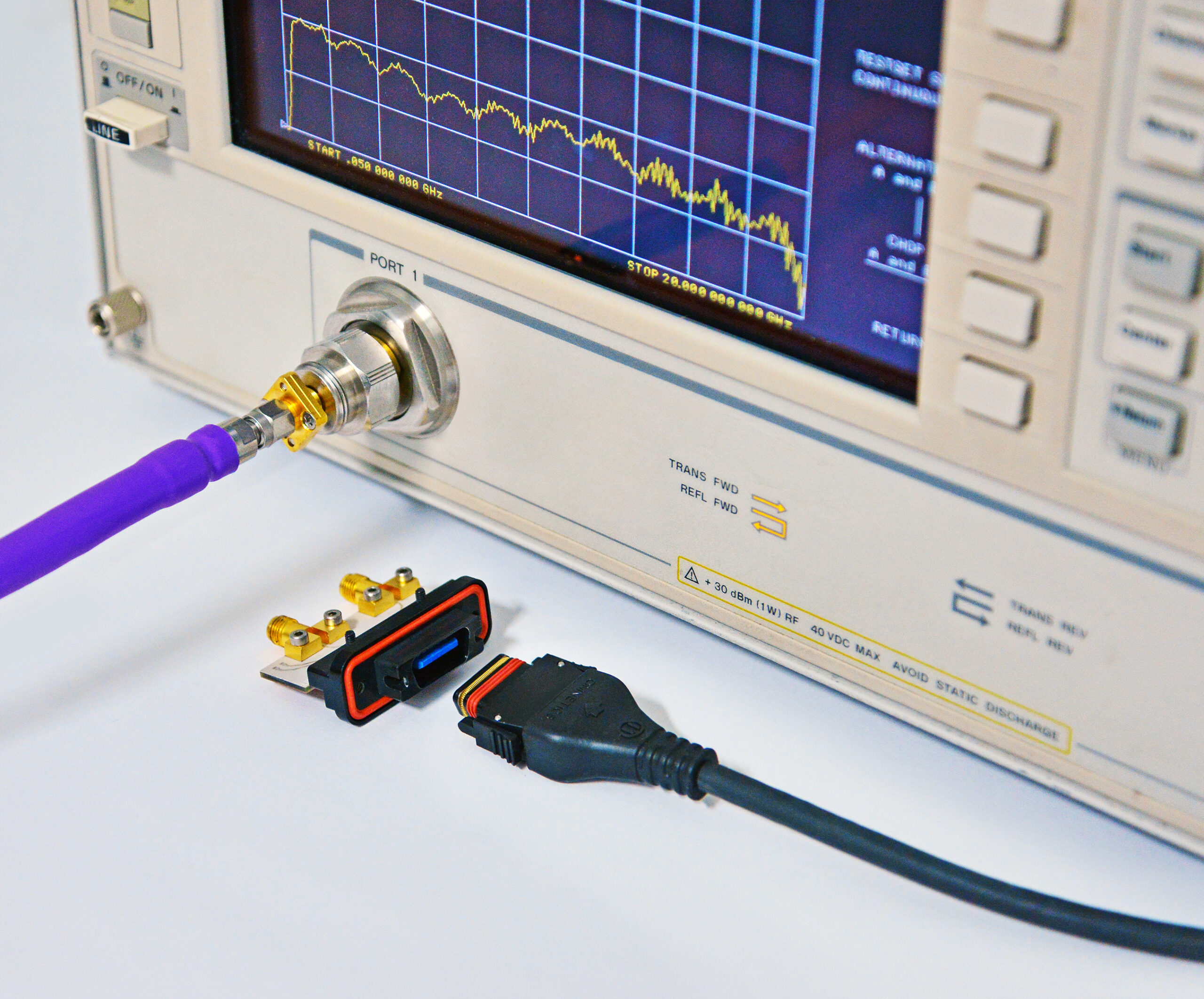

For

characterization and verification, Omnetics has an in-house Signal Integrity

Lab that is equipped with state-of-the-art testing equipment, including a

4-port Keysight PNA with Keysight PLTS for post-processing analysis. This provides

the ability to characterize and verify the performance of all Omnetics products,

as well as provide production testing for impedance upon request.

Omnetics

prides itself on providing accurate and reliable signal integrity data for all applications. Test reports are available for many

configurations. Additionally, S-parameter models (whether it’s from simulation

or measurement) are available upon request. Customs designs can even be models

and simulated to to provide S-parameter models that are specific to your

applications.