Material Selection & Finishing

Omnetics’ connectors and harnesses are manufactured from a broad array of modern engineered materials. Our molded plastic components are typically comprised of either reinforced Liquid Crystal Polymer (LCP) or Polyphenylene Sulfide (PPS) to achieve high strength, very thin walls and excellent dielectric properties. If you need a customized machined insulator in your design we would recommend an unfilled Polyetheretherketone or an unfilled Polyetherimide both of which offer good machinability, excellent high temperature stability and excellent dielectric properties.

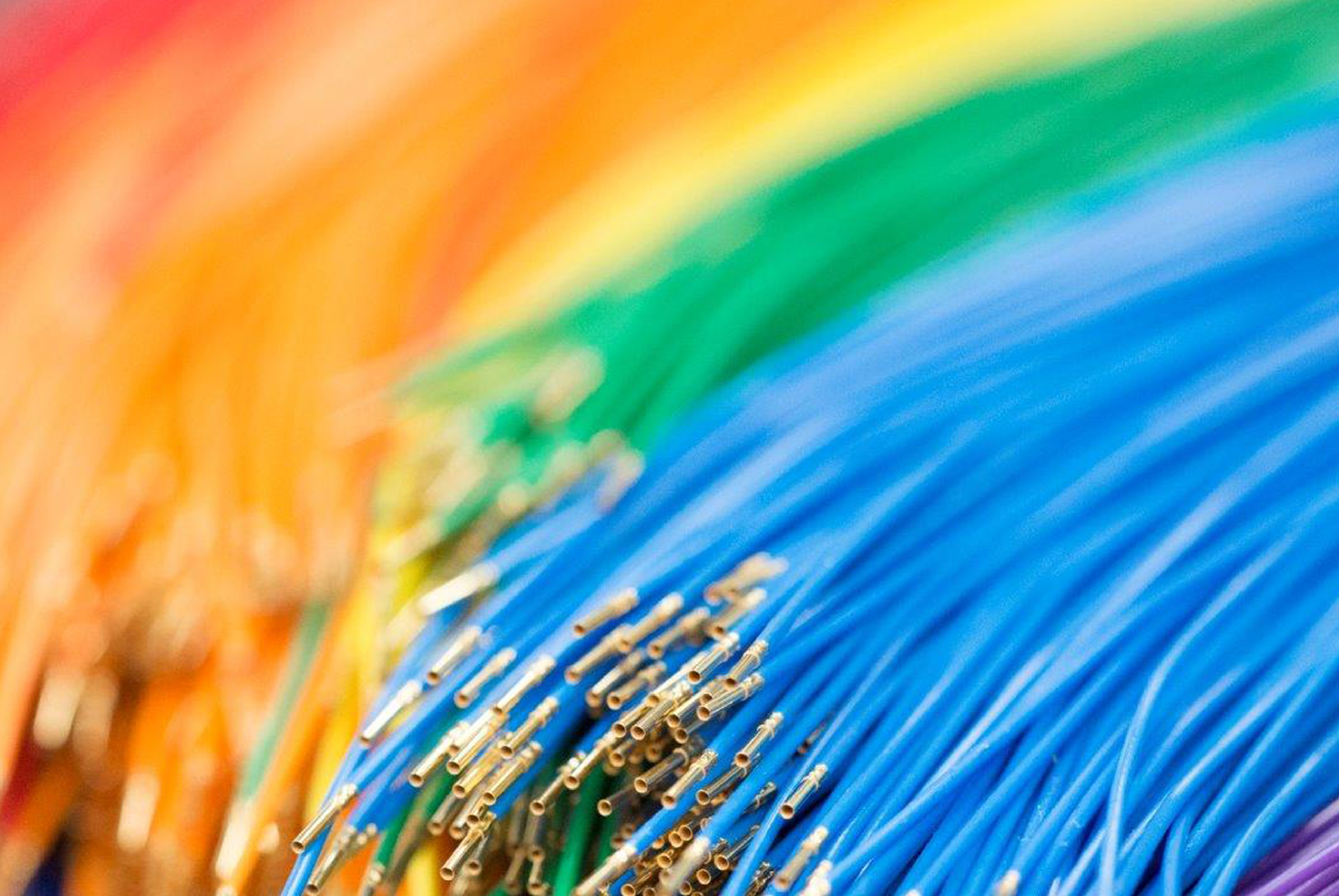

Cable material options are another important factor in the successful transfer of signals and power in your system. Although Omnetics does not manufacture cables in house, we have extensive experience in processing them and work with the most capable cable manufacturers around. Manufacturing a cable using a variety of fine stranded, small gage primaries with features like controlled impedance, strength members, braided shields and tough jacketing materials is a challenge and our select vendors can consistently meet your requirements. Below are some typical cable jacket material properties.

|

Jacket Material Properties |

||||

|

Jacket |

Polyurethane |

SantopreneTM |

Silicone |

PVC |

|

Ruggedness |

Very High |

Moderate |

Low |

Moderate |

|

Autoclavability |

Low |

High |

Very High |

Low-Moderate |

|

Cleanability |

Low-Moderate |

Moderate |

High |

Moderate-High |

|

Max |

90 |

135 |

180 |

105 |

|

Flexibility |

High |

Moderate |

Very High |

Low-Moderate |

|

Cost |

Moderate |

Low-Moderate |

High |

Low |

|

Wearability |

Moderate |

Moderate |

Low |

Moderate-High |

Typical Cable Considerations:

· Autoclave

· Flexibility

· Signal Integrity

· High/Low Temperature

· Triboelectric Noise

· RF Compatibility

· Ruggedness

· Sterilization

· Tensile Strength

· Flex life

· High-Speed Digital

· Miniaturization

· Biocompatibility

· Dielectric Strength

· Cost

Interested in a custom design for a wire harness application? Please contact a representative.