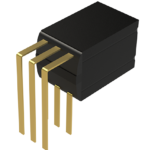

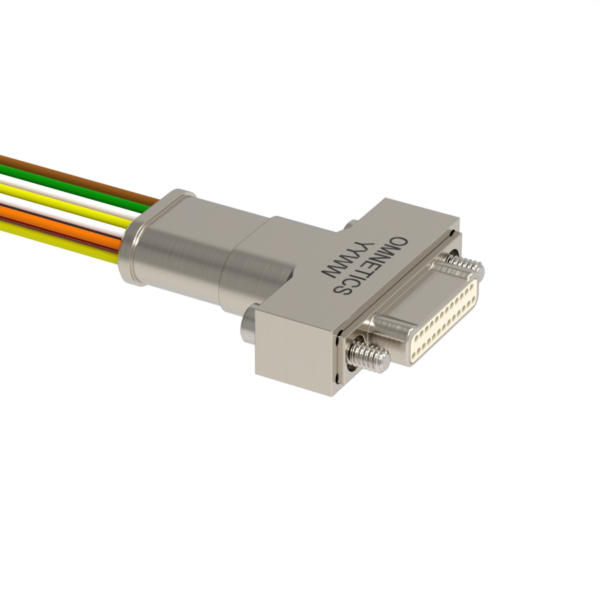

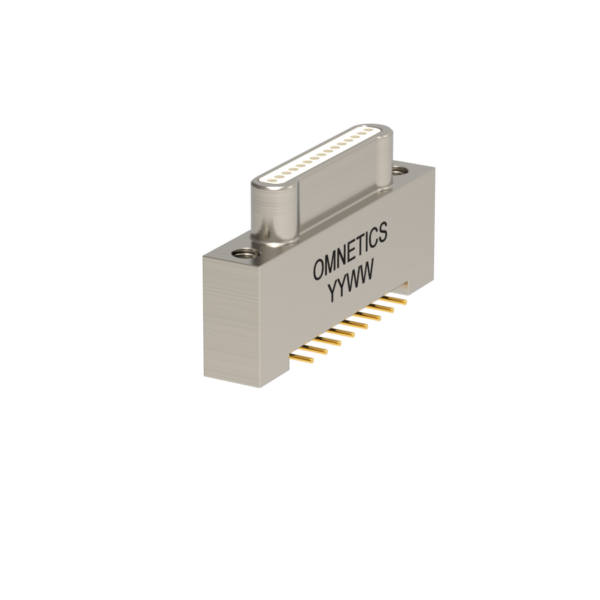

Nano-D / Bi-Lobe® Connectors – Dual Row -Thru-Hole Vertical (V4)

$1.00

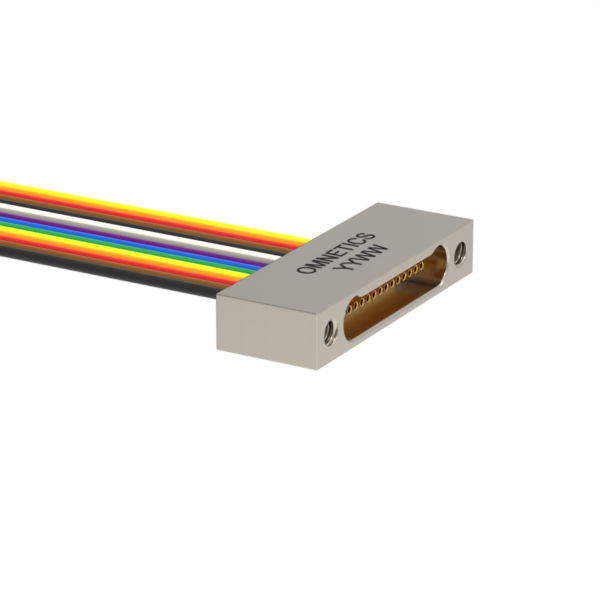

The Dual Row Nano-D / Bi-Lobe® V4 offers a low mass vertical thru-hole mounted orientation, making it ideal for high shock & vibration environments.

Resources

| Title | Type | File |

| Nano-D / Bi-Lobe® Connectors – Dual Row -Thru-Hole Vertical (V4) Contact | Download | |

| Nano-D / Bi-Lobe® Connectors – Dual Row -Thru-Hole Vertical (V4) Ordering Guide | Download | |

| Nano-D / Bi-Lobe® Connectors – Dual Row -Thru-Hole Vertical (V4) Hardware & Misc. | Download |

Description

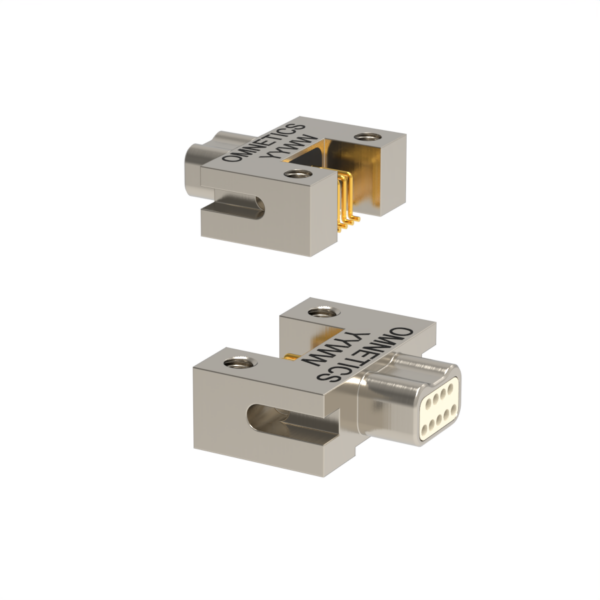

The Dual Row Nano-D / Bi-Lobe® V4 offers a low mass vertical thru-hole mounted orientation, making it ideal for high shock & vibration environments. These ruggedized nanos have contacts arranged on .025″ (.64 mm) center lines. The tails are spread into a mounting pattern on .050 (1.27 mm) centers, allowing space for the routing of traces and size of annular rings.

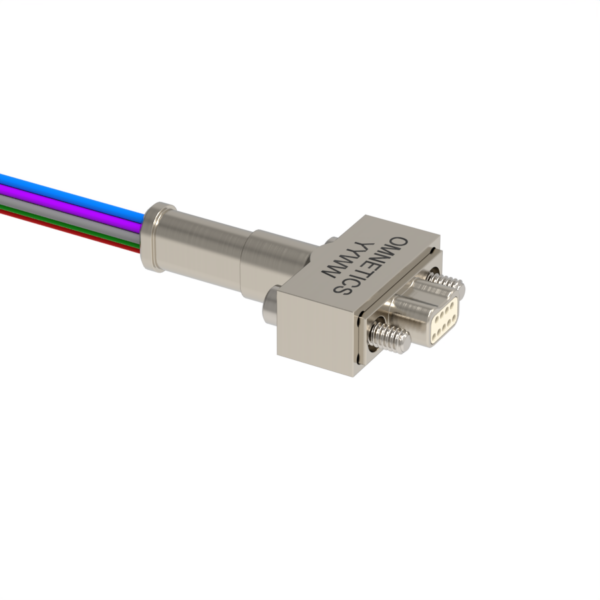

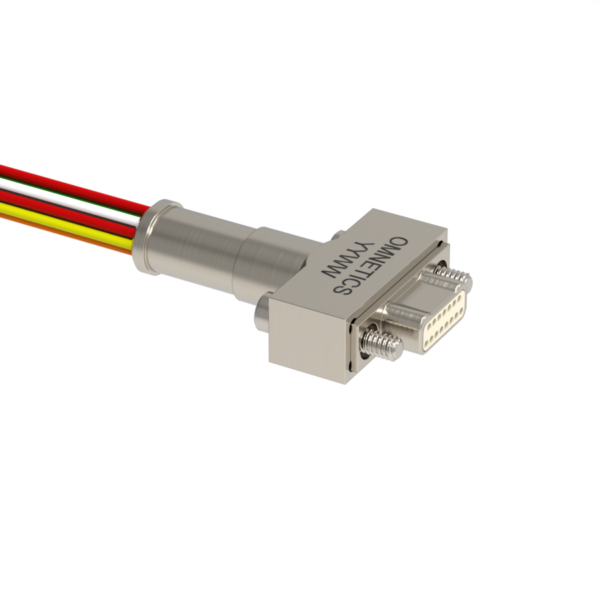

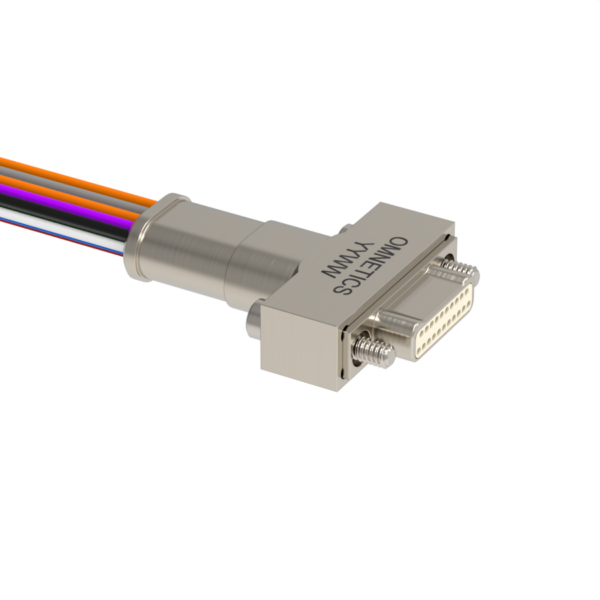

These connectors feature Omnetics highly dependable gold plated Flex Pin contact system conforming to the requirements of MIL-DTL-32139. These durable lightweight connectors are perfect for the most demanding applications and are intermateable with Omnetics QPL versions of Military Specification MIL-DTL-32139.

They are available with retention screws for a positive lock. These connectors are available in standard sizes ranging from 9 through 65 positions, as well as custom configuration

Additional information

| Omnetics Series |

MNPO ,MNSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

V4 – Vertical Thru-Hole |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS Sea Level |

| Contact Resistance |

71 mV Drop @ 1 AMP |

| Current Rating |

1 AMP per contact |

| Durability |

200 Mating cycles min* |

| Insulation Resistance |

5000 megohms min @ 100 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.1% max VCM |

| Mating/Unmating Force |

7 oz. (198 g) max per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Aluminum Shell, Electroless Nickel Plated Aluminum Shell, Black AnodizedAluminum Shell, Cadmium PlatedTitanium Shell, UnplatedStainless Steel Shell, Passivated |

| Insulator |

Liquid Crystal Polymer per MIL-DTL-32139 or PEEK |

| Pin |

Gold Plated BeCu |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

Features

The Dual Row Nano-D / Bi-Lobe® V4 offers a low mass vertical thru-hole mounted orientation, making it ideal for high shock & vibration environments. These ruggedized nanos have contacts arranged on .025″ (.64 mm) center lines. The tails are spread into a mounting pattern on .050” (1.27 mm) centers, allowing space for the routing of traces and size of annular rings.

These connectors feature Omnetics’ highly dependable gold plated Flex Pin contact system conforming to the requirements of MIL-DTL-32139. These durable lightweight connectors are perfect for the most demanding applications and are intermateable with Omnetics’ QPL versions of Military Specification MIL-DTL-32139.

They are available with retention screws for a positive lock. These connectors are available in standard sizes ranging from 9 through 65 positions, as well as custom configuration

Specifications

| Omnetics Series |

MNPO ,MNSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

V4 – Vertical Thru-Hole |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS Sea Level |

| Contact Resistance |

71 mV Drop @ 1 AMP |

| Current Rating |

1 AMP per contact |

| Durability |

200 Mating cycles min* |

| Insulation Resistance |

5000 megohms min @ 100 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.1% max VCM |

| Mating/Unmating Force |

7 oz. (198 g) max per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Aluminum Shell, Electroless Nickel Plated Aluminum Shell, Black AnodizedAluminum Shell, Cadmium PlatedTitanium Shell, UnplatedStainless Steel Shell, Passivated |

| Insulator |

Liquid Crystal Polymer per MIL-DTL-32139 or PEEK |

| Pin |

Gold Plated BeCu |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |