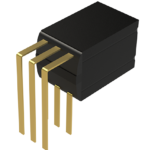

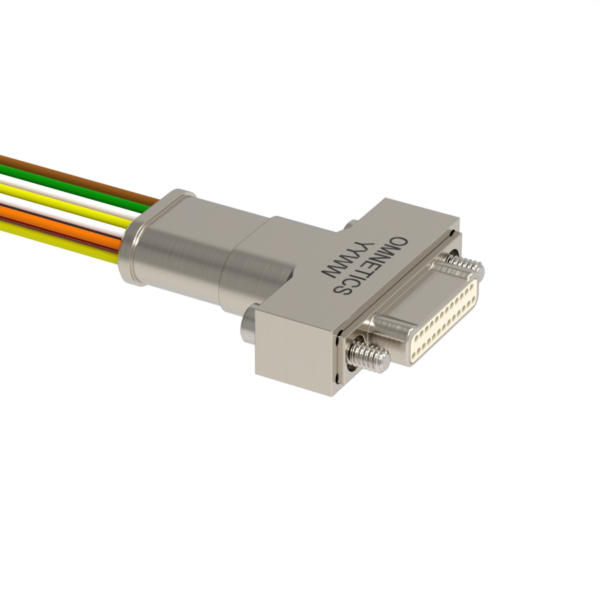

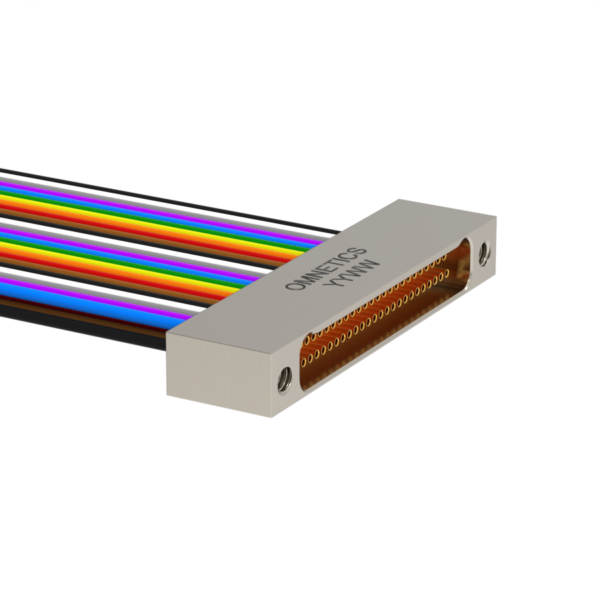

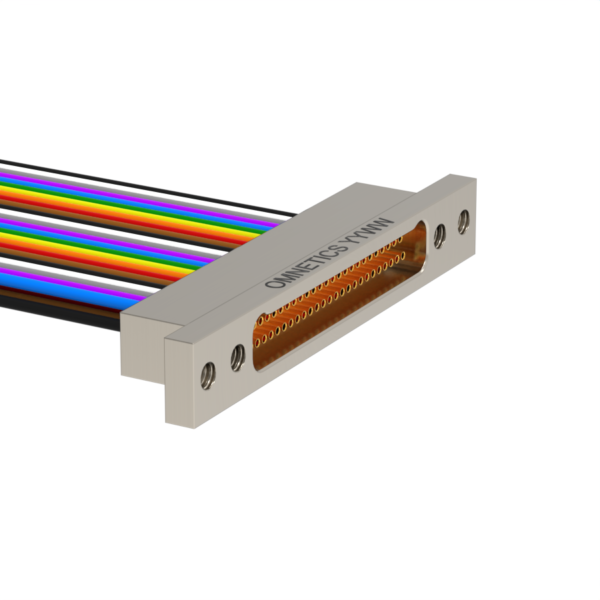

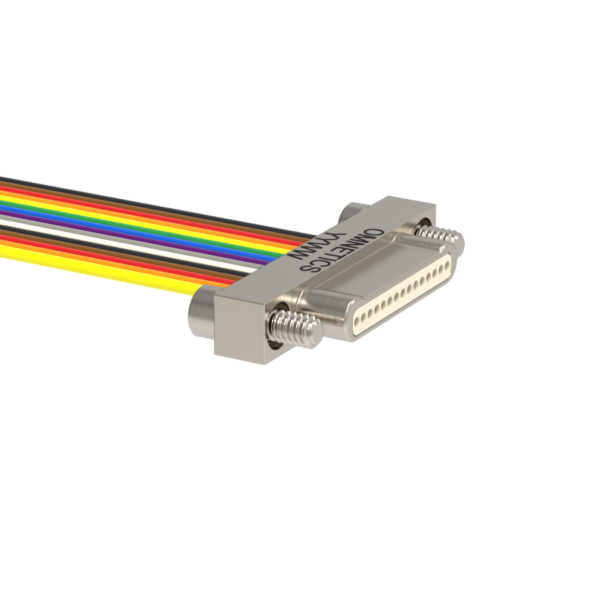

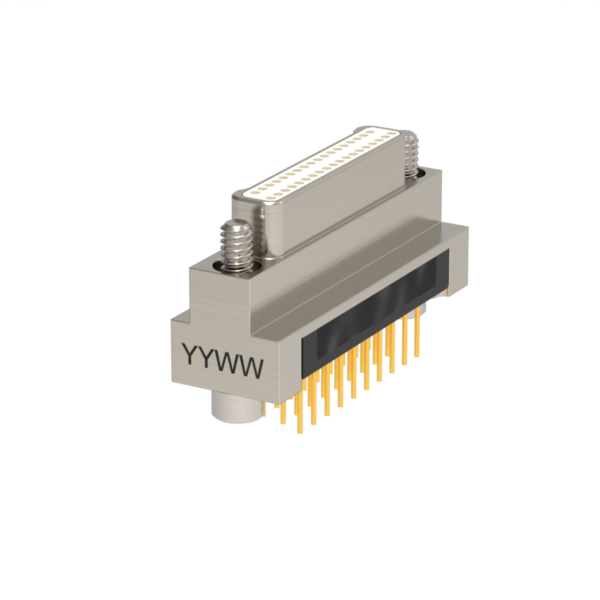

Nano-D / Bi-Lobe® Connectors – Dual Row – Flex Mount (FF)

$1.00

Flex Mount Bi-Lobe® Nano-D’s are a low profile ruggedized connector on .025 (.64 mm) centerlines.

Resources

| Title | Type | File |

| Nano-D / Bi-Lobe® Connectors – Dual Row – Flex Mount (FF) Contact | Download | |

| Nano-D / Bi-Lobe® Connectors – Dual Row – Flex Mount (FF) Ordering Guide | Download | |

| Nano-D / Bi-Lobe® Connectors – Dual Row – Flex Mount (FF) Hardware & Misc. | Download |

Description

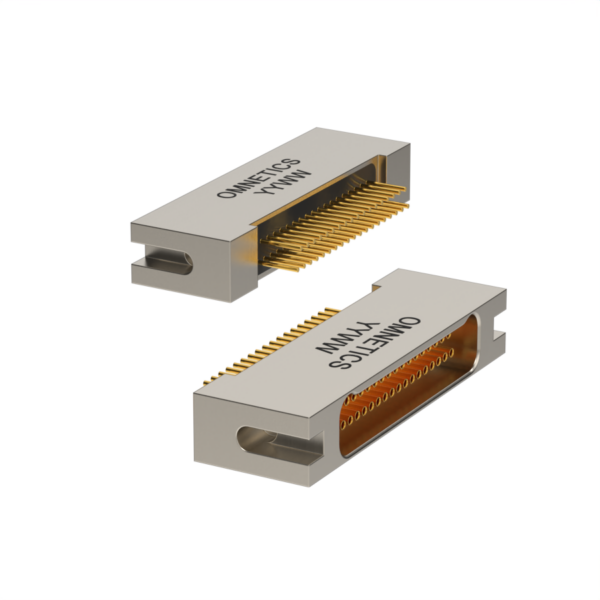

Flex Mount Bi-Lobe® Nano-D’s are a low profile ruggedized connector on .025 (.64 mm) centerlines. The SMT tails are formed together in an hourglass shape, allowing a double sided flex circuit to slide between the 2 rows. The spring tension holds the flex in place during the soldering process.

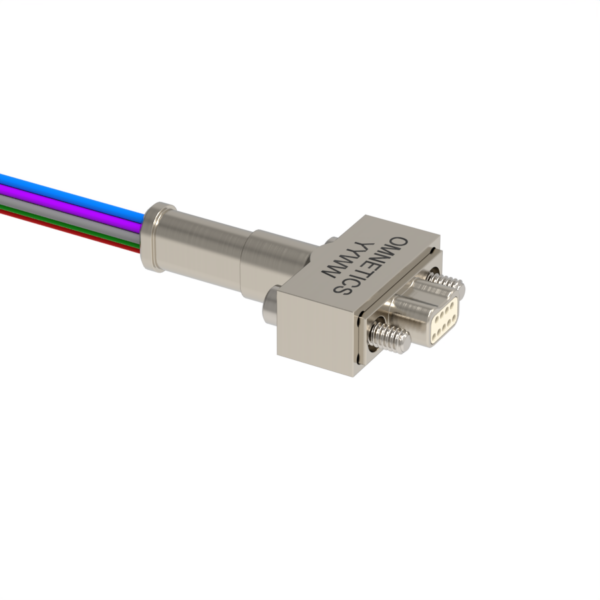

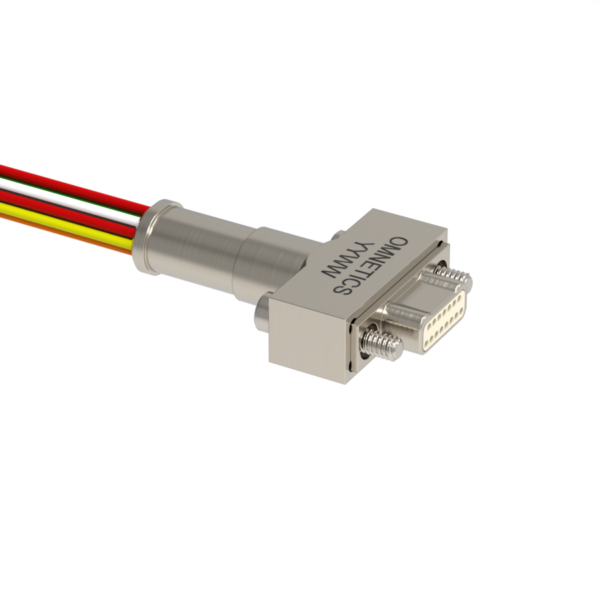

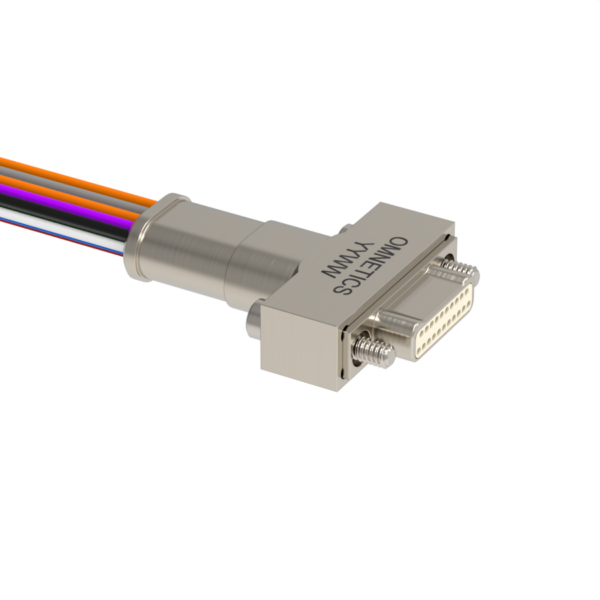

These connectors feature Omnetics highly reliable gold plated Flex Pin contact system conforming to the requirements of MIL-DTL-32139. These durable lightweight connectors are suitable for the most demanding applications. These connectors are available in standard sizes ranging from 9 through 65 positions, as well as custom configurations.

Flex design and installation service is also available from Omnetics. Please contact us for more information.

Additional information

| Omnetics Series |

MNPO ,MNSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS Sea Level |

| Contact Resistance |

71 mV Drop @ 1 AMP |

| Current Rating |

1 AMP per contact |

| Durability |

200 Mating cycles min* |

| Insulation Resistance |

5000 megohms min @ 100 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.1% max VCM |

| Mating/Unmating Force |

7 oz. (198 g) max per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Aluminum Shell, Electroless Nickel Plated Aluminum Shell, Black AnodizedAluminum Shell, Cadmium PlatedTitanium Shell, UnplatedStainless Steel Shell, Passivated |

| Insulator |

Liquid Crystal Polymer per MIL-DTL-32139 or PEEK |

| Pin |

Gold Plated BeCu |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

Features

Flex Mount Bi-Lobe® Nano-D’s are a low profile ruggedized connector on .025” (.64 mm) centerlines. The SMT tails are formed together in an hourglass shape, allowing a double sided flex circuit to slide between the 2 rows. The spring tension holds the flex in place during the soldering process.

These connectors feature Omnetics’ highly reliable gold plated Flex Pin contact system conforming to the requirements of MIL-DTL-32139. These durable lightweight connectors are suitable for the most demanding applications. These connectors are available in standard sizes ranging from 9 through 65 positions, as well as custom configurations.

Flex design and installation service is also available from Omnetics. Please contact us for more information.

Specifications

| Omnetics Series |

MNPO ,MNSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS Sea Level |

| Contact Resistance |

71 mV Drop @ 1 AMP |

| Current Rating |

1 AMP per contact |

| Durability |

200 Mating cycles min* |

| Insulation Resistance |

5000 megohms min @ 100 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.1% max VCM |

| Mating/Unmating Force |

7 oz. (198 g) max per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Aluminum Shell, Electroless Nickel Plated Aluminum Shell, Black AnodizedAluminum Shell, Cadmium PlatedTitanium Shell, UnplatedStainless Steel Shell, Passivated |

| Insulator |

Liquid Crystal Polymer per MIL-DTL-32139 or PEEK |

| Pin |

Gold Plated BeCu |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |