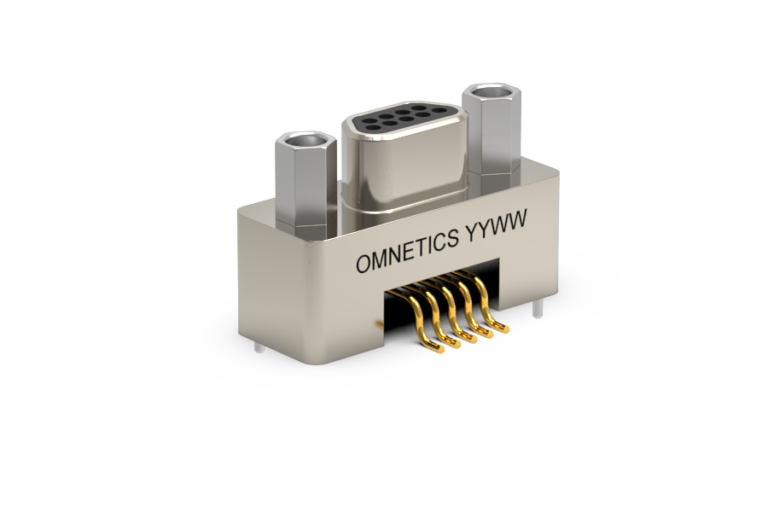

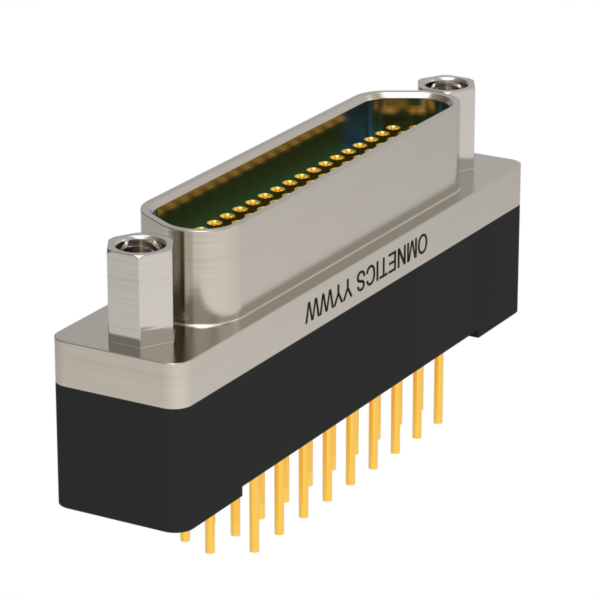

Nano 360® Twist Lock Metal Shell Circulars – Discrete Wired/Cable (TYPE WD/WC)

$1.00

Omnetics nano series of circular connectors are now available in a break away configuration.

Resources

| Title | Type | File |

| Nano 360® Circulars Twist Lock Panel Mount – Discrete Wired/Cable (TYPE WD/WC) Contact | Download | |

| Nano 360® Circulars Twist Lock Panel Mount – Discrete Wired/Cable (TYPE WD/WC) Ordering Guide | Download |

Description

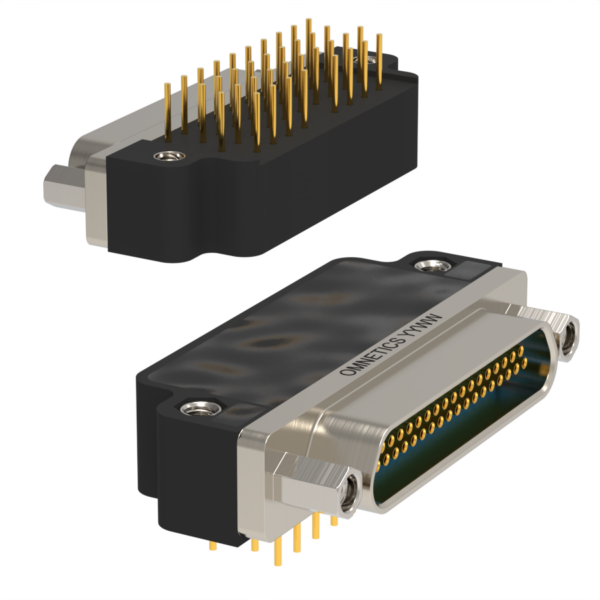

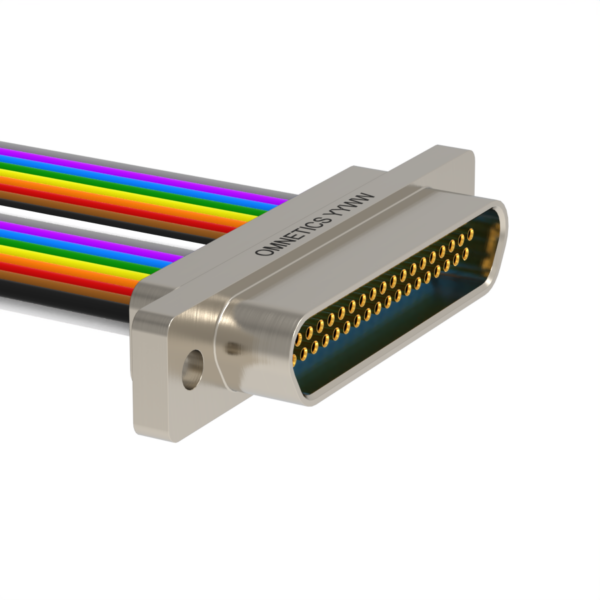

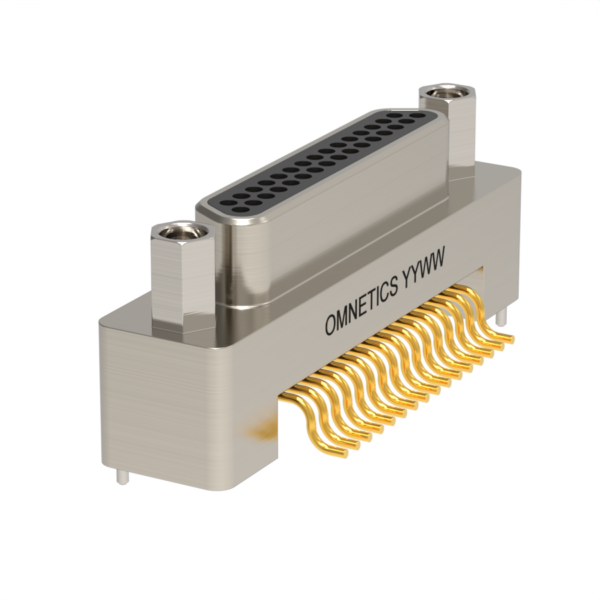

Omnetics nano series of circular connectors are now available in a break away configuration. These connectors are the smallest Mil-Quality circulars available today. With the ability to withstand high shock and vibrations while maintaining their electrical integrity, the break away feature is ideal for the most demanding applications where size and ruggedness are valued. Designed with an extra retention spring these connectors are engineer to release (break away) at a pre-determined force. These connectors are also available with added waterproof sealing up to IP-68 for the mated pair.

These high density multi-position connectors are available in sizes from 2-28 positions and have contacts arranged on a .025 (.64 mm) pitch. Utilizing a military quality contact system these connectors are ideal for applications where size, weight and overall reliability are critical.

Additional information

| Omnetics Series |

TNCP ,TNCS |

|---|---|

| Rows |

1 Row |

| Termination Type |

WC – Cable ,WD – Discrete Leadwire |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS |

| Contact Resistance |

71 Milliohm Max (71 mV Drop Max) @ 1.0 AMPs |

| Current Rating |

1 AMP per contact |

| Durability |

200 cycles |

| Insulation Resistance |

5, 000 megohms min @ 500 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.03% max CVCM |

| Mating/Unmating Force |

2.5 oz (71 g) typical per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Ni Plated Brass or Black Ni. Contact Factory for other Materials |

| Insulator |

Thermoplastic Polymer, Per MIL-DTL-24519 |

| Pin |

Beryllium Copper per ASTM B194, Alloy C17200 |

| Socket |

Copper Alloy MIL-DTL-83513 |

| Encapsulant |

Epoxy |

Features

Omnetics nano series of circular connectors are now available in a break away configuration. These connectors are the smallest Mil-Quality circulars available today. With the ability to withstand high shock and vibrations while maintaining their electrical integrity, the break away feature is ideal for the most demanding applications where size and ruggedness are valued. Designed with an extra retention spring these connectors are engineer to release (break away) at a pre-determined force. These connectors are also available with added waterproof sealing up to IP-68 for the mated pair.

These high density multi-position connectors are available in sizes from 2-28 positions and have contacts arranged on a .025” (.64 mm) pitch. Utilizing a military quality contact system these connectors are ideal for applications where size, weight and overall reliability are critical.

Specifications

| Omnetics Series |

TNCP ,TNCS |

|---|---|

| Rows |

1 Row |

| Termination Type |

WC – Cable ,WD – Discrete Leadwire |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

250 VAC RMS |

| Contact Resistance |

71 Milliohm Max (71 mV Drop Max) @ 1.0 AMPs |

| Current Rating |

1 AMP per contact |

| Durability |

200 cycles |

| Insulation Resistance |

5, 000 megohms min @ 500 VDC |

| Shock |

100 gs with no discontinuties > 10 nanoseconds |

| Vibration |

20 gs with no discontinuties > 10 nanoseconds |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.03% max CVCM |

| Mating/Unmating Force |

2.5 oz (71 g) typical per contact |

| Material Specifications |

– |

| Shell Material and Finish |

Ni Plated Brass or Black Ni. Contact Factory for other Materials |

| Insulator |

Thermoplastic Polymer, Per MIL-DTL-24519 |

| Pin |

Beryllium Copper per ASTM B194, Alloy C17200 |

| Socket |

Copper Alloy MIL-DTL-83513 |

| Encapsulant |

Epoxy |