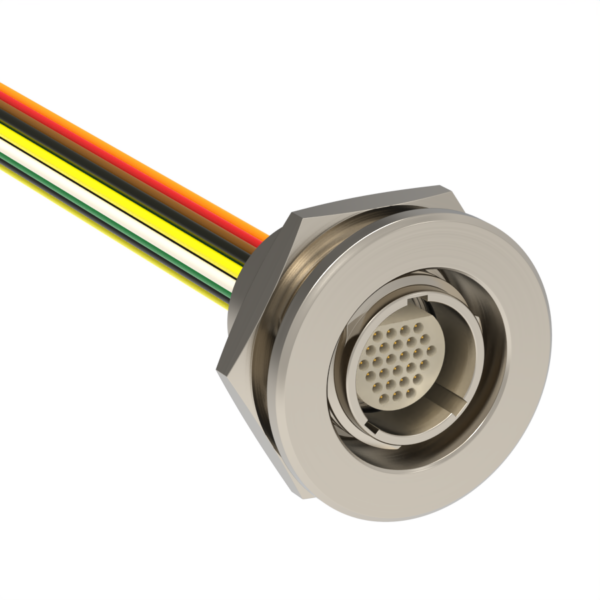

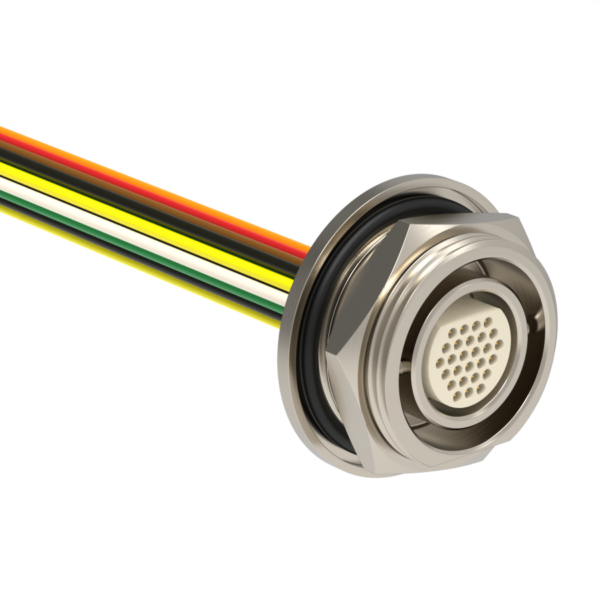

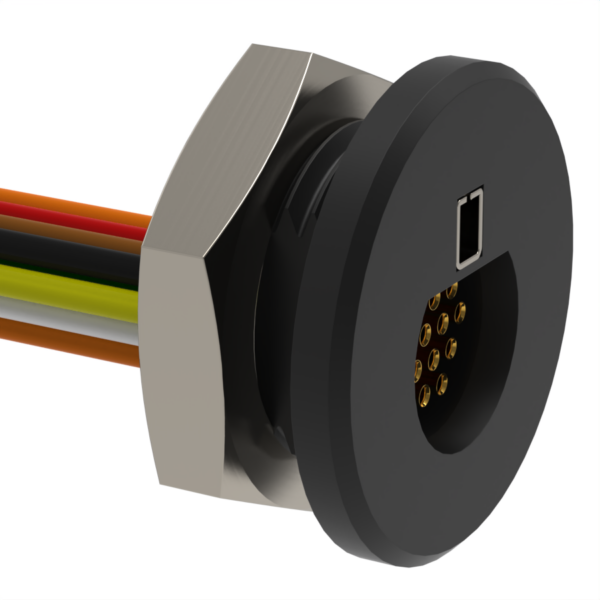

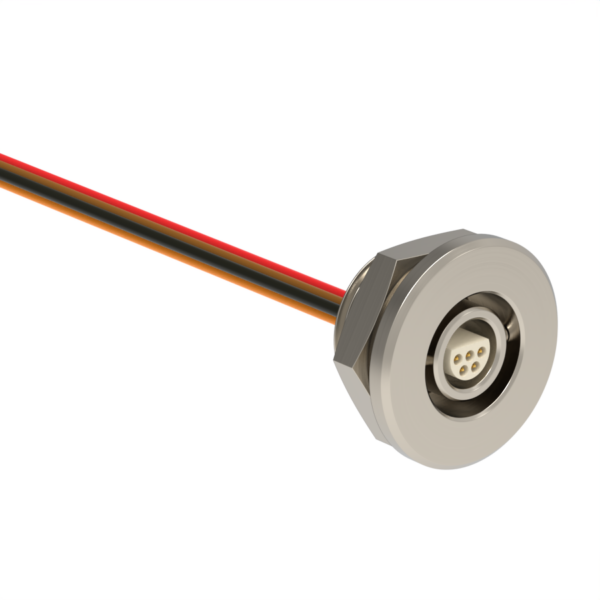

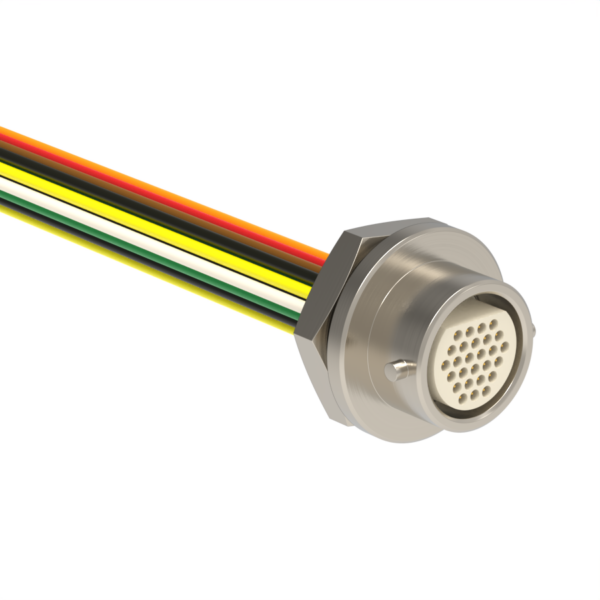

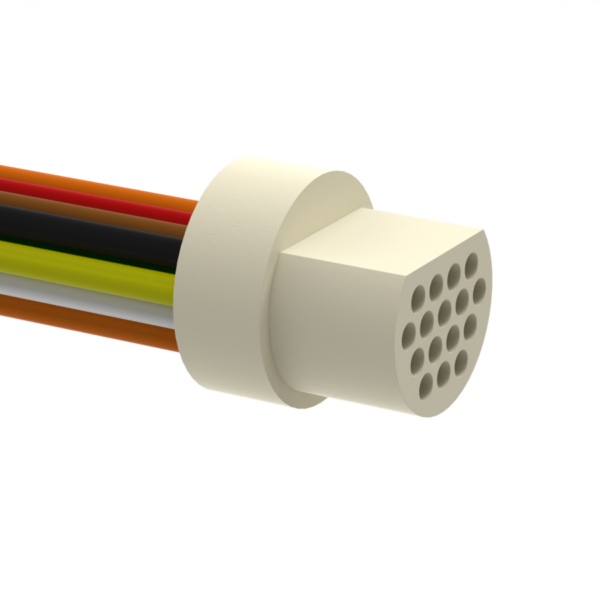

Micro 360® Plastic Circular Right Angle (RA)

$1.00

The Micro Circular Series utilizes Omnetics’ rugged and reliable Flex-Pin contact system.

Resources

| Title | Type | File |

| Micro 360® Plastic Circular Right Angle (RA) Contact | Download | |

| Micro 360® Plastic Circular Right Angle (RA) Ordering Guide | Download | |

| Micro 360® Plastic Circular Right Angle (RA) Accessories | Download |

Description

The Micro Circular Series utilizes Omnetics’ rugged and reliable Flex-Pin contact system. Spaced on 50 mil (1.27mm) centerlines they feature a mated length of less than 12.4 mm. Both the male and female contacts are shrouded by the plastic insulators insuring that the contacts are protected during mating and unmating. Outer diameters range from 5.6 mm to 10.0 mm. With the ability to withstand high shock and vibration while maintaining their electrical integrity, these connectors are ideal for the most demanding applications. Gold plated Beryllium Copper flex pins are capable of over 2,000 mating cycles.

5, 7, 12, 16, 27 & 39 positions housing sizes are available in pre-wired, soldercup and solid straight tail versions.Elaborate wire harnesses, flex termination, overmolding and custom shells are all available upon request

Additional information

| Omnetics Series |

MCP ,MCS |

|---|---|

| Rows |

2 Rows ,3 Rows ,4 Rows |

| Termination Type |

RA – Right Angle Thru-Hole |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms (65 mV) Max @ 2.5 AMPs |

| Current Rating |

3 AMPs per contact |

| Durability |

500 cycles |

| Insulation Resistance |

5, 000 megohms min @ 500 VDC |

| Shock |

50 gs with no discontinuties > 1 microsecond |

| Vibration |

20 gs with no discontinuties > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.03% max CVCM |

| Mating/Unmating Force |

Forces not to exceed 6 oz/contact |

| Material Specifications |

– |

| Insulator |

LCP per MIL-M-24519, Type GLCP-30F |

| Pin |

Beryllium Copper per ASTM B194, Alloy C17200 |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

| Standard Pin PCB Tail Termination |

Solder per J-STD-006 (Non-RoHS) |

| RoHS Pin PCB Tail Termination |

Hard gold plate per ASTM B488 |

| RoHS Socket PCB Tail Termination |

Hard gold plate per ASTM B488 |

Features

The Micro Circular Series utilizes Omnetics’ rugged and reliable Flex-Pin contact system. Spaced on 50 mil (1.27mm) centerlines they feature a mated length of less than 12.4 mm. Both the male and female contacts are shrouded by the plastic insulators insuring that the contacts are protected during mating and unmating. Outer diameters range from 5.6 mm to 10.0 mm. With the ability to withstand high shock and vibration while maintaining their electrical integrity, these connectors are ideal for the most demanding applications. Gold plated Beryllium Copper flex pins are capable of over 2,000 mating cycles.

5, 7, 12, 16, 27 & 39 positions housing sizes are available in pre-wired, soldercup and solid straight tail versions. Elaborate wire harnesses, flex termination, overmolding and custom shells are all available upon request.

Specifications

| Omnetics Series |

MCP ,MCS |

|---|---|

| Rows |

2 Rows ,3 Rows ,4 Rows |

| Termination Type |

RA – Right Angle Thru-Hole |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms (65 mV) Max @ 2.5 AMPs |

| Current Rating |

3 AMPs per contact |

| Durability |

500 cycles |

| Insulation Resistance |

5, 000 megohms min @ 500 VDC |

| Shock |

50 gs with no discontinuties > 1 microsecond |

| Vibration |

20 gs with no discontinuties > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML, 0.03% max CVCM |

| Mating/Unmating Force |

Forces not to exceed 6 oz/contact |

| Material Specifications |

– |

| Insulator |

LCP per MIL-M-24519, Type GLCP-30F |

| Pin |

Beryllium Copper per ASTM B194, Alloy C17200 |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

| Standard Pin PCB Tail Termination |

Solder per J-STD-006 (Non-RoHS) |

| RoHS Pin PCB Tail Termination |

Hard gold plate per ASTM B488 |

| RoHS Socket PCB Tail Termination |

Hard gold plate per ASTM B488 |