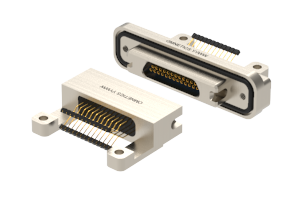

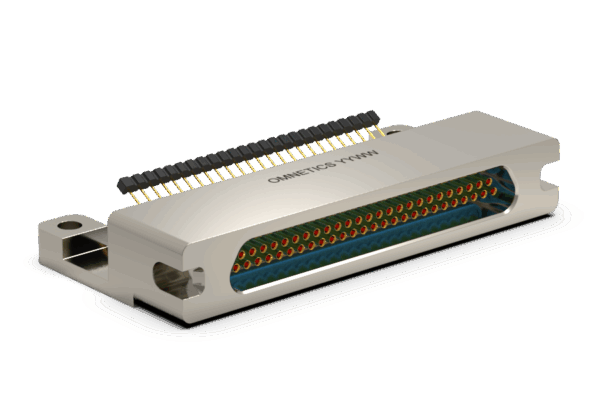

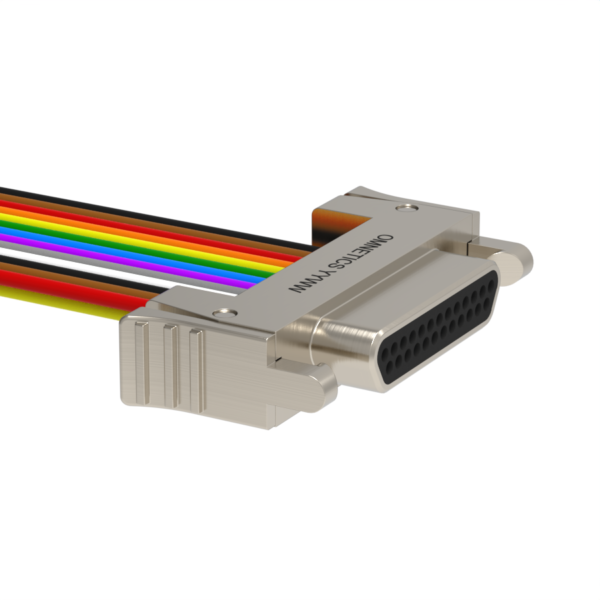

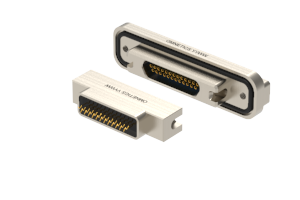

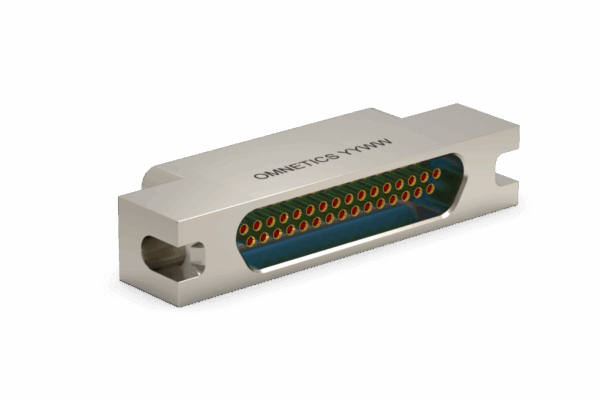

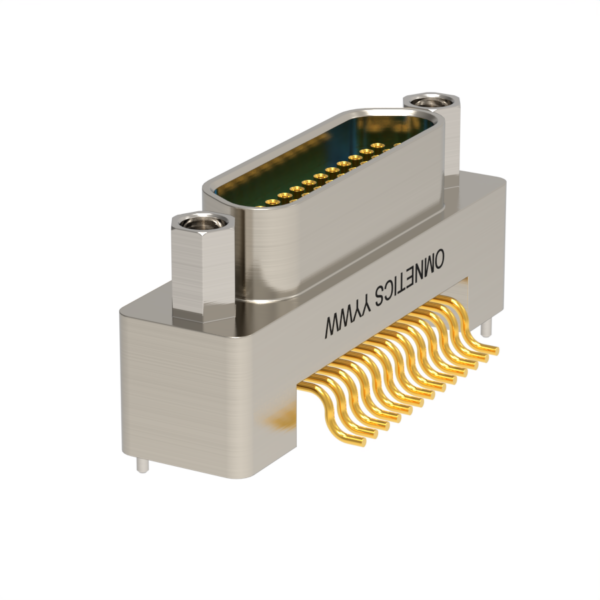

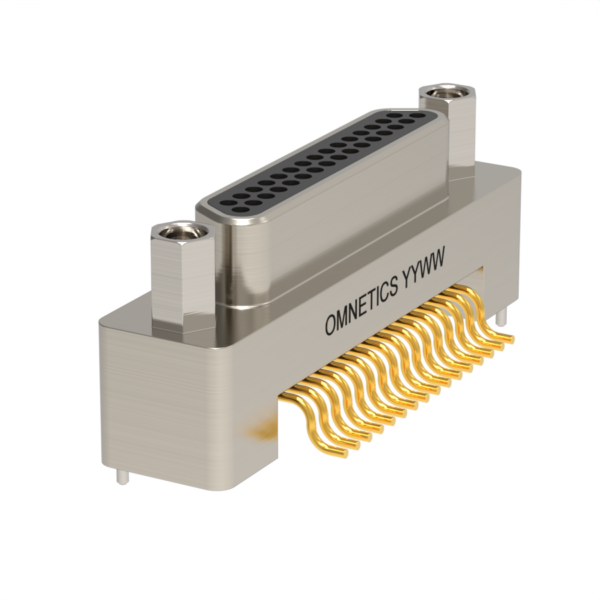

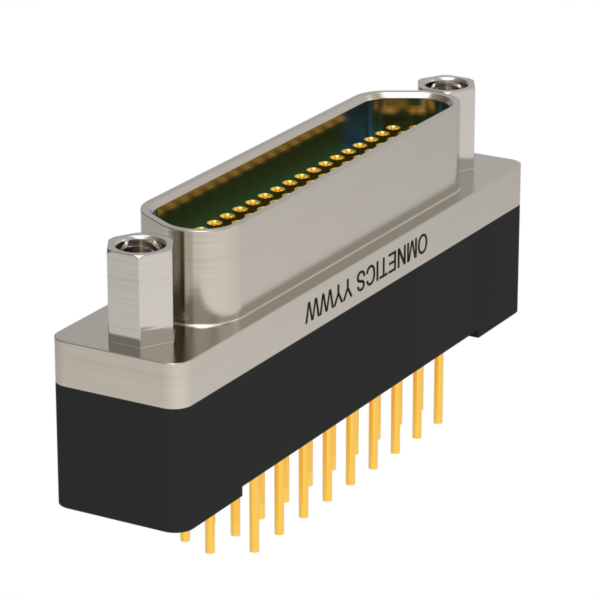

Low Profile Micro-D Straight Thru-Hole (DD)

$1.00

Low profile Micro-D micro-miniature connector series offers proven military spec performance and reliability with a reduced flange height and weight compared to standard Micro-D connectors.

Resources

| Title | Type | File |

| Low Profile Micro-D Straight Thru-Hole (DD) Contact | Download | |

| Low Profile Micro-D Straight Thru-Hole (DD) Ordering Guide | Download | |

| Low Profile Micro-D Straight Thru-Hole (DD) Hardware & Misc. | Download |

Description

Low profile Micro-D micro-miniature connector series offers proven military spec performance and reliability with a reduced flange height and weight compared to standard Micro-D connectors. These connectors meet or exceed the performance requirement of MIL-DTL-83513 and are intended for high reliability board to wire I/O and wire-to-wire applications including high-temperature applications. The Low profile Micro-D connectors are available with 9 to 37 contacts and come with a variety of termination, hardware, and wiring options.

Additional information

| Omnetics Series |

MDLP ,MDLS |

|---|---|

| Rows |

2 Rows |

| Termination Type |

DD – Thru-Hole Straight |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS @sea level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

| Aluminum Shell, Black Anodized |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Black Anodize per MIL-A-8625\, Type II\, Class 2 |

| Stainless Steel Shell, Passivated |

300 Series\, Passivated per SAE AMS-2700 |

Features

Low profile Micro-D micro-miniature connector series offers proven military spec performance and reliability with a reduced flange height and weight compared to standard Micro-D connectors. These connectors meet or exceed the performance requirement of MIL-DTL-83513 and are intended for high reliability board to wire I/O and wire-to-wire applications including high-temperature applications. The Low profile Micro-D connectors are available with 9 to 37 contacts and come with a variety of termination, hardware, and wiring options.

Specifications

| Omnetics Series |

MDLP ,MDLS |

|---|---|

| Rows |

2 Rows |

| Termination Type |

DD – Thru-Hole Straight |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS @sea level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

| Aluminum Shell, Black Anodized |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Black Anodize per MIL-A-8625\, Type II\, Class 2 |

| Stainless Steel Shell, Passivated |

300 Series\, Passivated per SAE AMS-2700 |