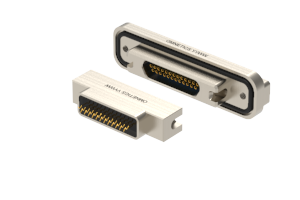

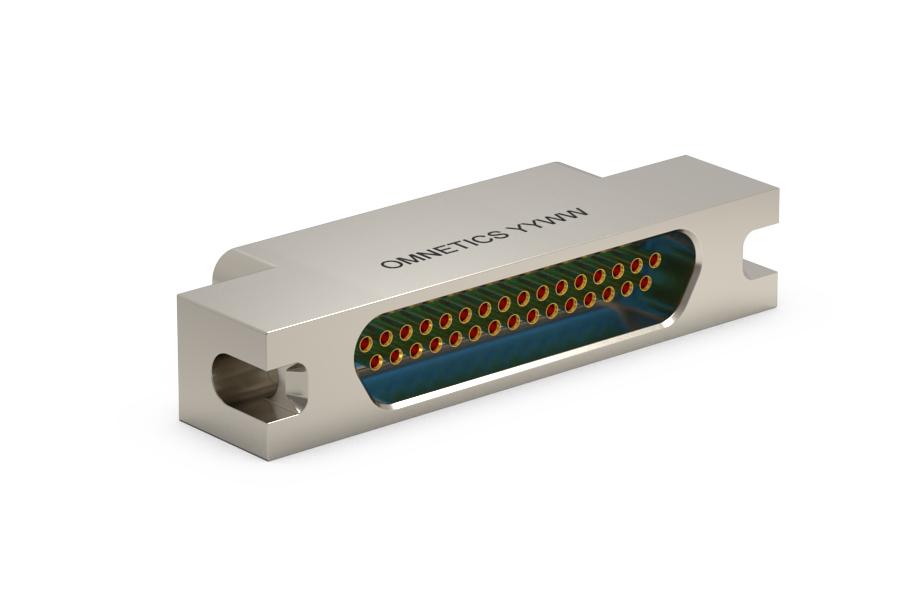

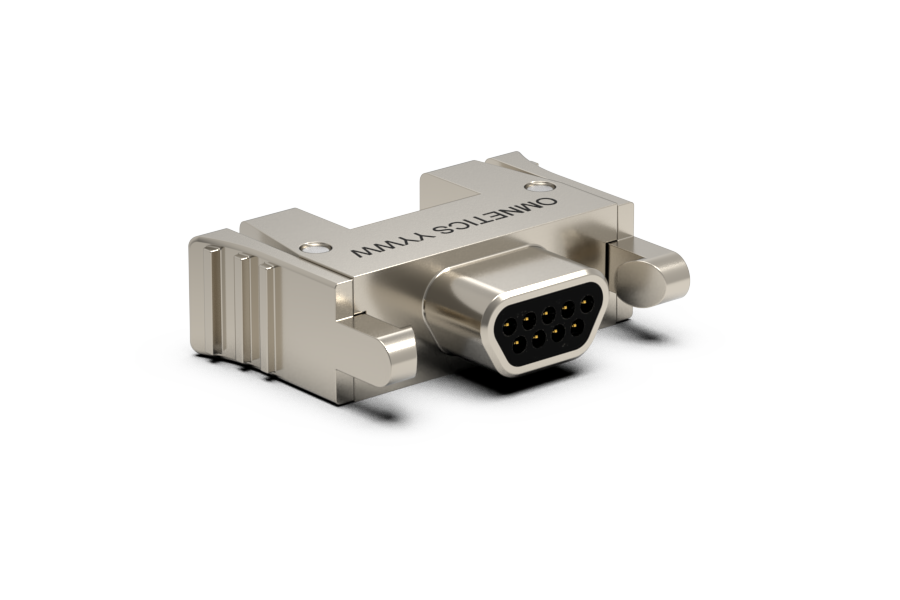

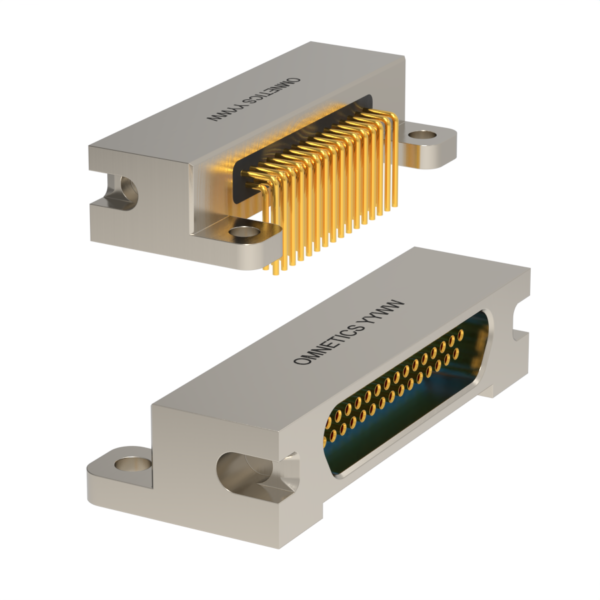

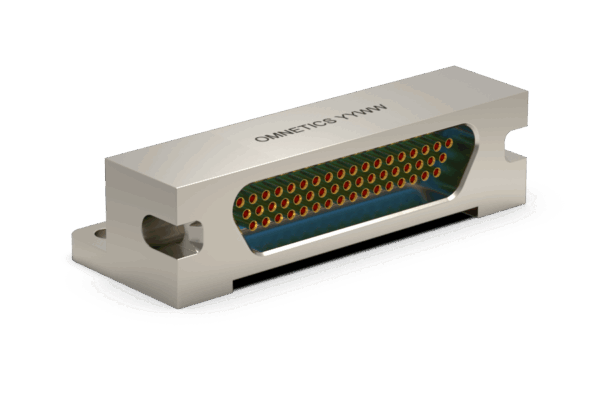

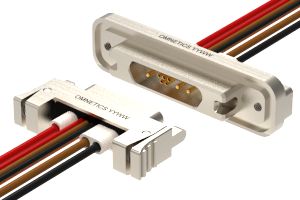

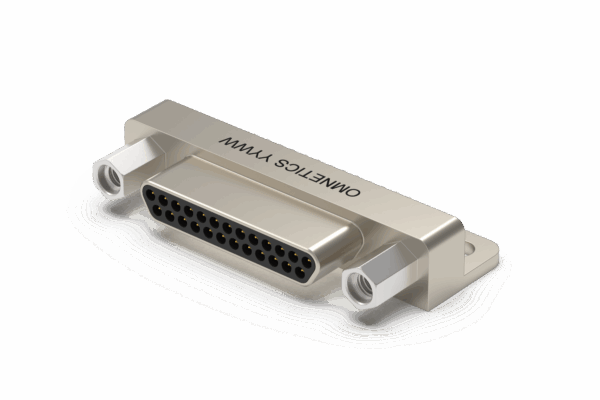

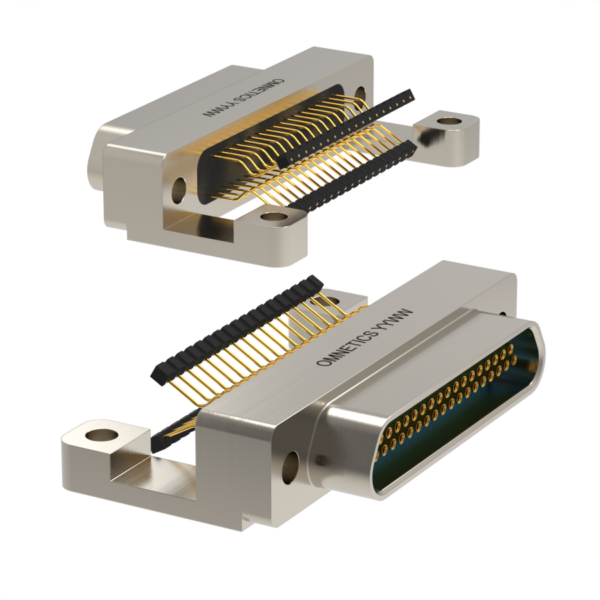

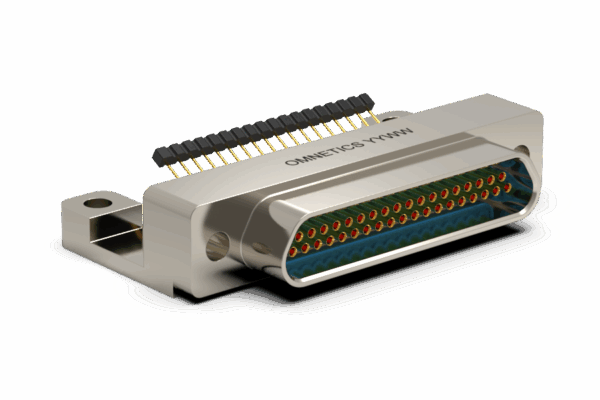

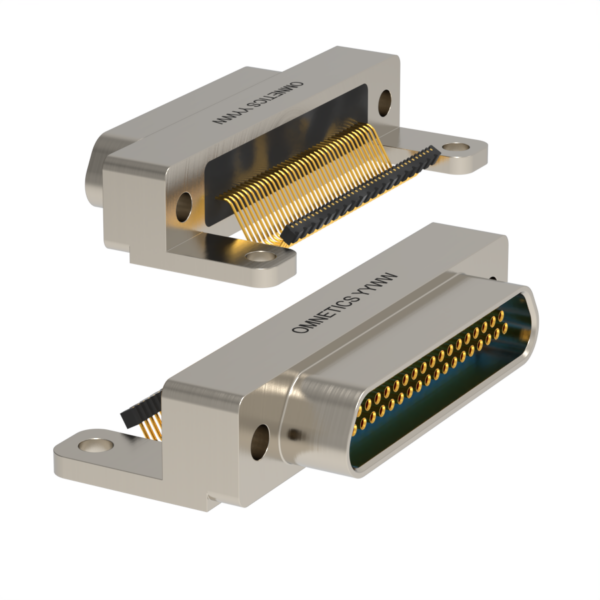

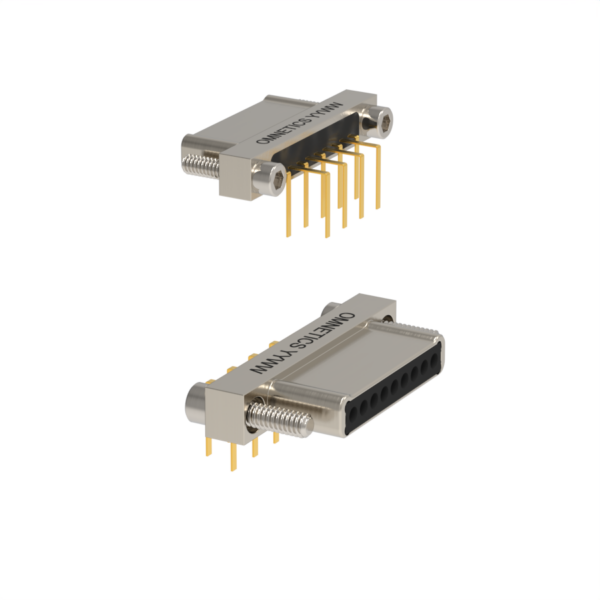

Latching Micro-D Flex Circuit Mount (FF)

$1.00

Omnetics Latching Micro-D connectors offer a rugged quick latch system.

Resources

| Title | Type | File |

| Latching Micro-D Flex Circuit Mount (FF) Contact | Download | |

| Latching Micro-D Flex Circuit Mount (FF) Ordering Guide | Download | |

| Latching Micro-D Flex Circuit Mount (FF) Hardware & Misc. | Download |

Description

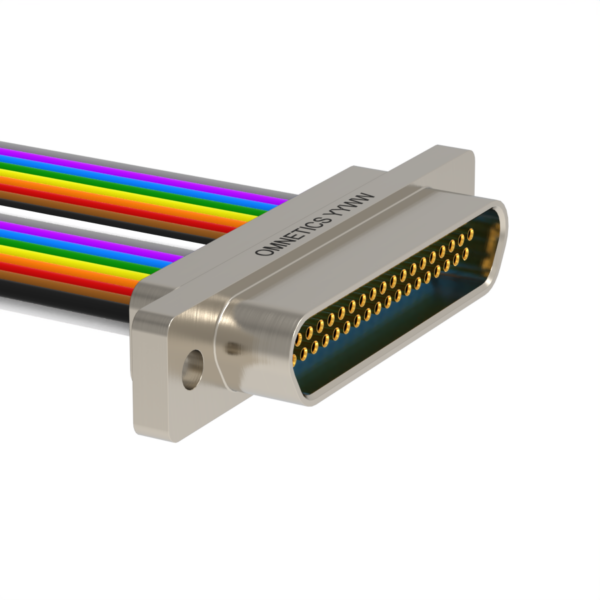

Omnetics Latching Micro-D connectors offer a rugged quick latch system. The Latching Micro-D connectors are availbale in sizes 9-51 and use Omnetics Flex Pin contact system, which meets all the standard performance requirements of MIL-DTL-83513, including shock and vibration. These connectors provide a secure connection without the need for tools and jacking hardware and are available in wired, board mount, panel mount configurations as well as with back shell options.

Additional information

| Omnetics Series |

LMDS |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Latch |

Stainless Steel, Nickel Plated |

| Latch Spring |

Stainless Steel |

| Retaining Pin |

Stainless Steel |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

Features

Omnetics’ Latching Micro-D connectors offer a rugged quick latch system. The Latching Micro-D connectors are availbale in sizes 9-51 and use Omnetics’ Flex Pin contact system, which meets all the standard performance requirements of MIL-DTL-83513, including shock and vibration. These connectors provide a secure connection without the need for tools and jacking hardware and are available in wired, board mount, panel mount configurations as well as with back shell options.

Specifications

| Omnetics Series |

LMDS |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Latch |

Stainless Steel, Nickel Plated |

| Latch Spring |

Stainless Steel |

| Retaining Pin |

Stainless Steel |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |