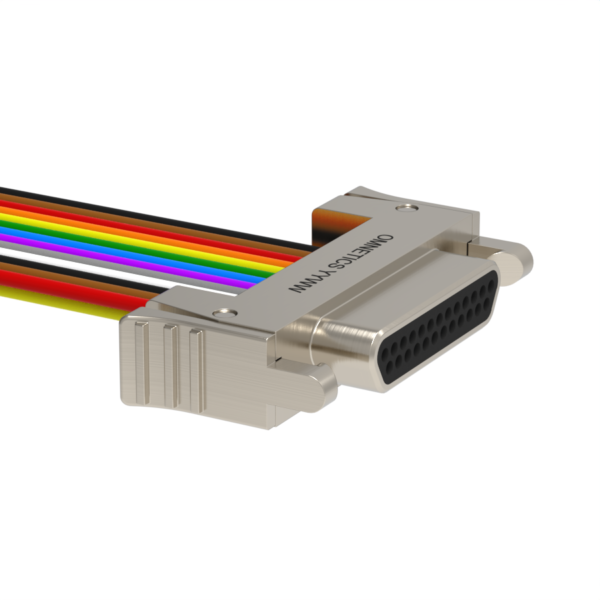

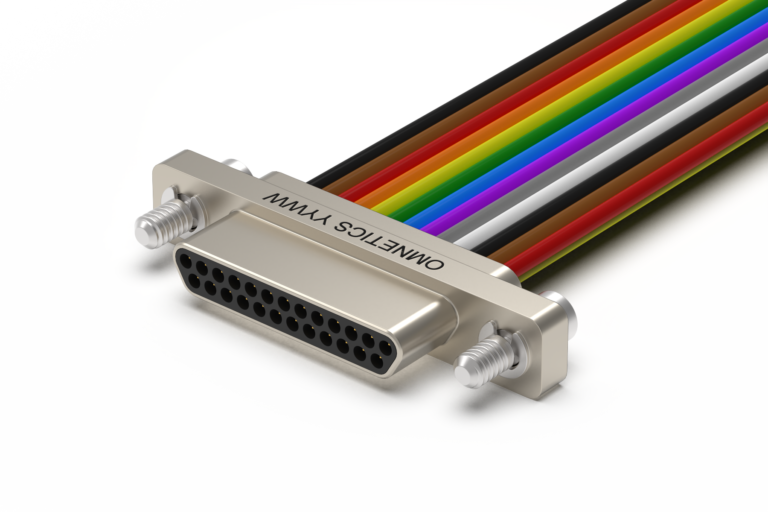

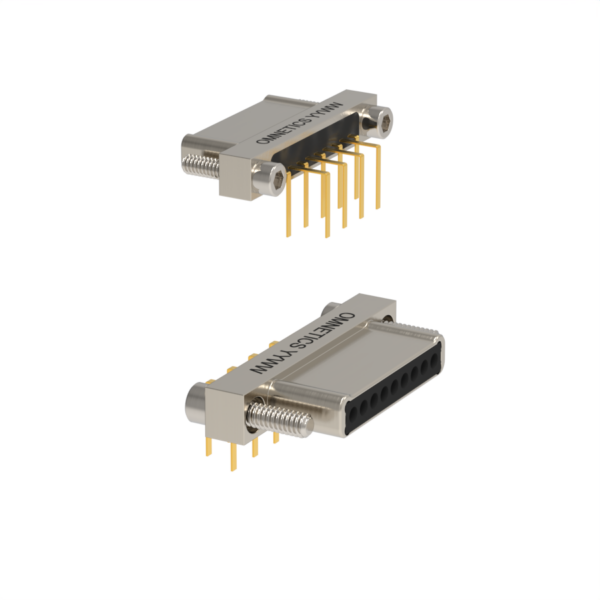

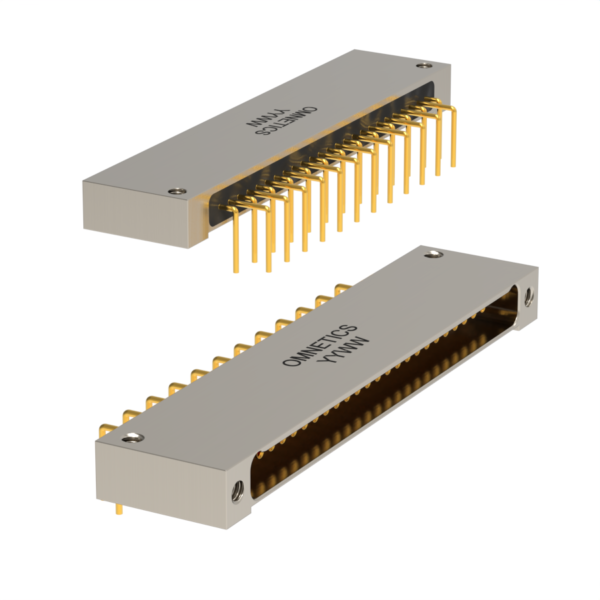

Micro-D Jumpers (WXY)

$1.00

Omnetics Micro-D subminiature connectors are QPL qualified and designed and manufactured to meet and exceed MIL-DTL-83513

Resources

| Title | Type | File |

| Micro-D Jumpers (WXY) Contact | Download | |

| Micro-D Jumpers (WXY) Ordering Guide | Download | |

| Micro-D Jumpers (WXY) Hardware & Misc. | Download |

Description

Omnetics Micro-D subminiature connectors are QPL qualified and designed and manufactured to meet and exceed MIL-DTL-83513. The connector assembly is built to assure the highest performance through high shock and vibration applications as well as extreme environmental use. They use the proven beryllium copper spring pin to socket contact system plated with both nickel and gold that assures the highest quality for mating and de-mating and very low contact resistance. Pin and sockets are set at .050 center to center lines. Our standard and COTs models are available in pin counts from 9 through 51 positions and come available in solder cup and wired as well as board mount configurations. The collection of Micro-D connectors also includes special high temperature versions, deep space versions with NASA qualified low outgassing, as well as mixed signal designs fabricated to match your application directly.

Additional information

| Omnetics Series |

JUM |

|---|---|

| Rows |

1 Row ,2 Rows ,3 Rows ,4 Rows |

| Connector 1 |

MMDP ,MMDS |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS @sea level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 g's with no discontinuities > 1 microsecond |

| Vibration |

20 g's with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

| Aluminum Shell, Black Anodized |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Black Anodize per MIL-A-8625\, Type II\, Class 2 |

| Stainless Steel Shell, Passivated |

300 Series\, Passivated per SAE AMS-2700 |

Features

- Sizes 9, 15, 21, 25, 31, 37 and 51 are available with two contact rows

- Size 51 is available with three rows contact rows

- Mating Pin & Socket models available

- Male to Female, Male to Male and Female to Female connector types available

- RoHS available upon request

- High Temp Epoxy available upon request

Specifications

| Omnetics Series |

JUM |

|---|---|

| Rows |

1 Row ,2 Rows ,3 Rows ,4 Rows |

| Connector 1 |

MMDP ,MMDS |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS @sea level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 g's with no discontinuities > 1 microsecond |

| Vibration |

20 g's with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

| Aluminum Shell, Black Anodized |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Black Anodize per MIL-A-8625\, Type II\, Class 2 |

| Stainless Steel Shell, Passivated |

300 Series\, Passivated per SAE AMS-2700 |