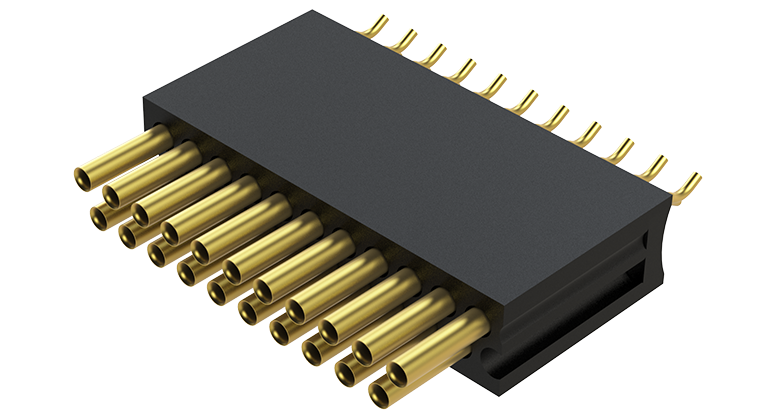

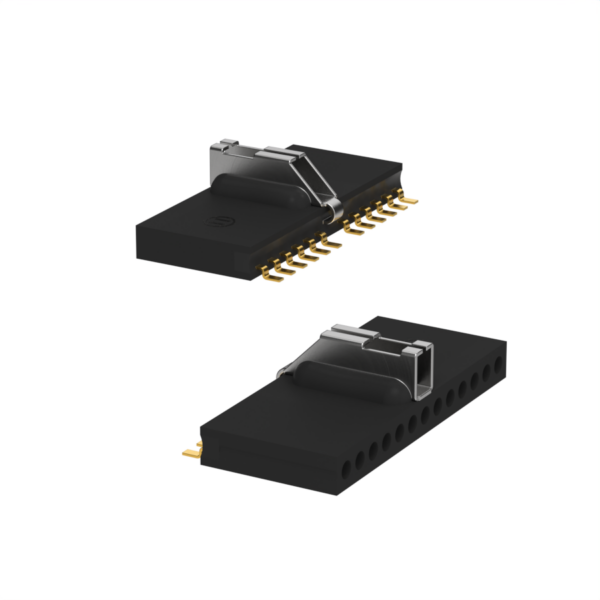

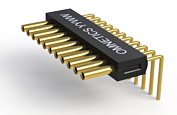

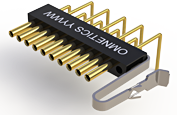

Dual Row Offset Flex Tail (FF)

$1.00

Flex mount offset Micro Strip connectors are a low profile ruggedized connector on .050 (1.27 mm) centerlines.

Resources

| Title | Type | File |

| Dual Row Offset Flex Tail (FF) Contact | Download | |

| Dual Row Offset Flex Tail (FF) Ordering Guide | Download |

Description

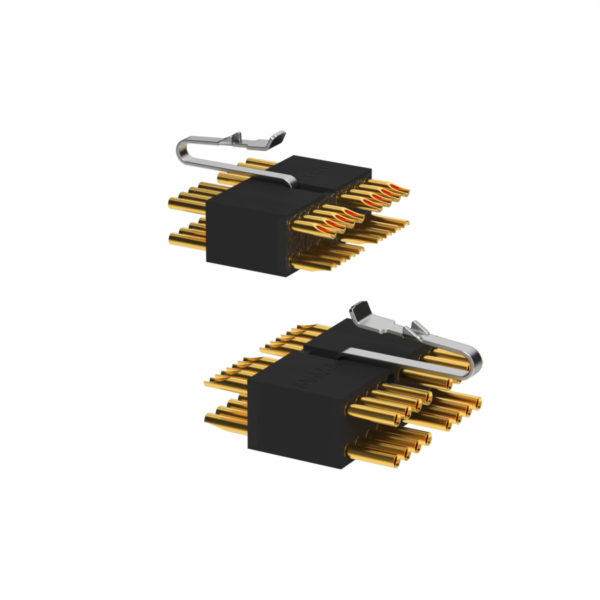

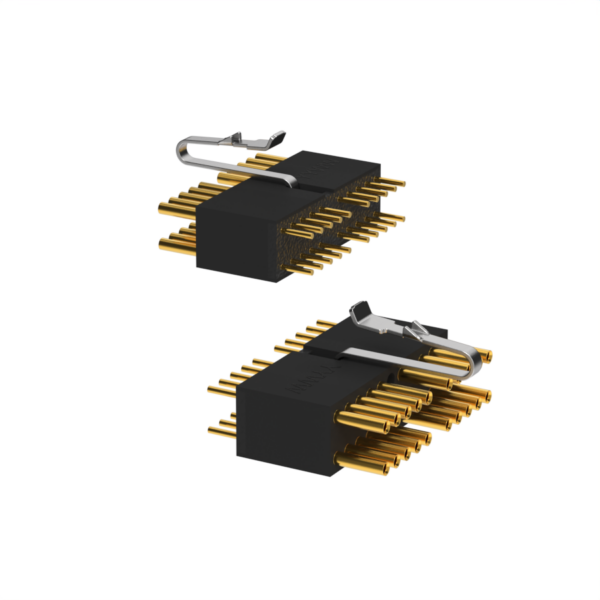

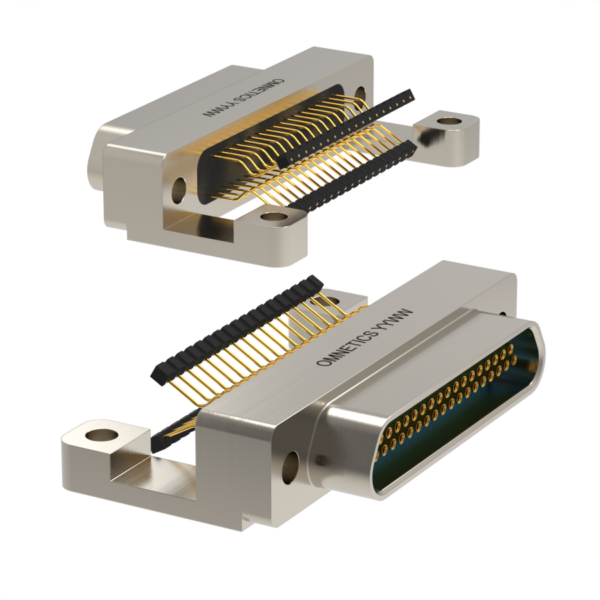

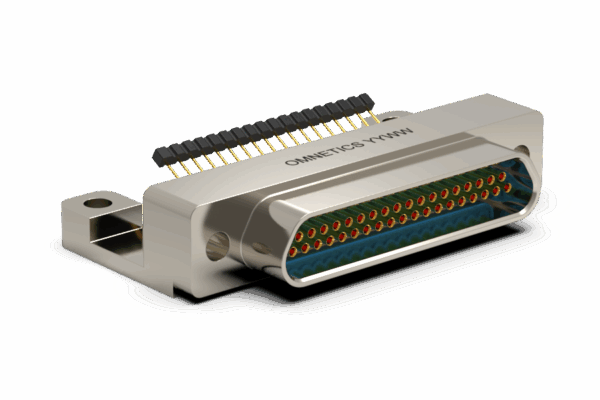

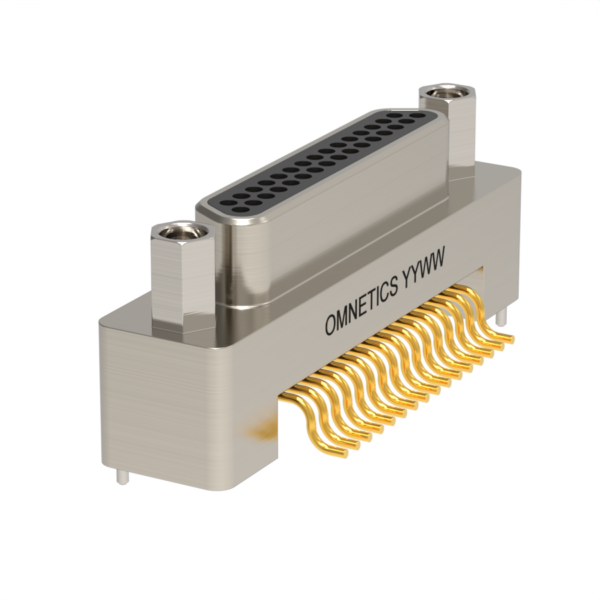

Flex mount offset Micro Strip connectors are a low profile ruggedized connector on .050 (1.27 mm) centerlines. The SMTtails are formed together in an hourglass shape, allowing a double sided flex circuit to slide between the 2 rows of leads. The spring tension holds the flex in place during the soldering process. These durable light weight connectors are suitable for the most demanding applications. They are available with mounting holes suitable for PCB and flex mounting, and feature Omnetics’ highly reliable gold plated Flex Pin contact system which meets the performance specifications of MIL-DTL-83513. These connectors are available in standard sizes ranging from 2 through 97 positions as well as custom configurations. Flex design and installation service is also available from Omnetics. Please contact us for more information.

Additional information

| Omnetics Series |

PSM ,SSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS Sea Level |

| Contact Resistance |

26 milliohms (65 mV max @ 2.5 AMPs) |

| Current Rating |

3 AMPs per contact |

| Durability |

500 Cycles |

| Insulation Resistance |

5, 000 Megohms min @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

NASA SP-R-0022 |

| Mating/Unmating Force |

Forces not to exceed 6 oz/contact |

| Material Specifications |

– |

| Insulator |

Polyphenylene Sulfide per MIL-M-24519 |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

| Standard Pin PCB Tail Termination |

Solder per J-STD-006 (Non-RoHS) or ASTM P-81728 |

| RoHS Pin PCB Tail Termination |

Hard gold plate per ASTM B488 |

| RoHS Socket PCB Tail Termination |

Hard gold plate per ASTM B488 |

Features

Flex mount offset Micro Strip connectors are a low profile ruggedized connector on .050” (1.27 mm) centerlines. The SMTtails are formed together in an hourglass shape, allowing a double sided flex circuit to slide between the 2 rows of leads. The spring tension holds the flex in place during the soldering process. These durable light weight connectors are suitable for the most demanding applications. They are available with mounting holes suitable for PCB and flex mounting, and feature Omnetics’ highly reliable gold plated Flex Pin contact system which meets the performance specifications of MIL-DTL-83513. These connectors are available in standard sizes ranging from 2 through 97 positions as well as custom configurations. Flex design and installation service is also available from Omnetics. Please contact us for more information.

Specifications

| Omnetics Series |

PSM ,SSO |

|---|---|

| Rows |

2 Rows |

| Termination Type |

FF – Flex Tail |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS Sea Level |

| Contact Resistance |

26 milliohms (65 mV max @ 2.5 AMPs) |

| Current Rating |

3 AMPs per contact |

| Durability |

500 Cycles |

| Insulation Resistance |

5, 000 Megohms min @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

NASA SP-R-0022 |

| Mating/Unmating Force |

Forces not to exceed 6 oz/contact |

| Material Specifications |

– |

| Insulator |

Polyphenylene Sulfide per MIL-M-24519 |

| Socket |

Gold Plated Copper Alloy |

| Encapsulant |

Epoxy |

| Standard Pin PCB Tail Termination |

Solder per J-STD-006 (Non-RoHS) or ASTM P-81728 |

| RoHS Pin PCB Tail Termination |

Hard gold plate per ASTM B488 |

| RoHS Socket PCB Tail Termination |

Hard gold plate per ASTM B488 |