High Speed Connector Family

Today’s design engineers have a strong directive when it comes to military electronics, and much of the emphasis seems focused heavily around SWaP.

But what is SWaP and why is it so important?

SWaP (Size, Weight, and Power) is a major challenge for designers tasked with the development of modern-day electrical and computer equipment. Whether your design focuses on a soldier worn computing device or something fixed, the physical Size, Weight and Power of the system are critical for determining its overall effectiveness.

Gone are the days of analog

In addition to military issued weaponry, today’s modern warfighters are carrying enough computing power to fuel an entire factory. From field radios to portable surveillance systems, each device has its own job to do, and each device is responsible for distributing power and signals accordingly. These devices include GPS, night-vision aids as well as Wi-Fi hotspots capable of transmitting real-time battlefield intelligence in some of the harshest environments on the planet.

The main challenge when designing SWaP-optimized electronics is finding the delicate balance between size, weight, and power consumption, without physically compromising the devices’ overall performance, durability, and reliability. Many advanced avionics platforms today are processing mountains of data, and in doing so, are consuming more power than ever before. This requires today’s engineers to design embedded electronics and interconnect systems differently, so they can handle increased data speeds and bandwidth without adding significant weight.

Omnetics Connector Corporation’s engineers have been able to lend their expertise to this issue by releasing a new set of miniaturized high-speed standards featuring ruggedized USB 3.0 (3.1 Gen 1), HDMI and Cat6a offerings. This new family of miniature circulars allows designers the ability to transmit un-interrupted, high-speed digital signals in some of the smallest mil-spec footprints on the market.

Omnetics, a Mil-Spec connector manufacturer, has been designing circular configurations for over 30 years, and in order to make these already robust connectors even more rugged and watertight, the process of injection overmolding was added to this family of interconnect standards. Consisting of shielded polyurethane cables, these battlefield tested circulars feature a flat black overmold allowing for a seamless IP68 seal, with the signal integrity to match. Each high-speed configuration utilizes Omnetics’ patented flex-pin gold plated contacts that are polarized and shrouded by a unique liquid crystal polymer insulator. The overmolded shells are keyed to ensure easy mate-ability in the field with one hand (gloved or bare). Blind-mate-ability is no longer an issue—Omnetics’ ruggedized shell features a polarized triple-key configuration to make even the tough connection seem easy. Fully encased in the polyurethane mold hides a 360° shielded solution, terminated to a banding platform designed into the shell to ensure the highest levels of signal integrity are achieved.

Omnetics High-Speed interconnect family provides the reliability and ruggedness expected from Omnetics connectors, with the speed to match the following protocols:

Ruggedized Nano 360® USB 3.0 (USB 3.1 Gen 1)

Ruggedized Nano 360® USB 3.0 (USB 3.1 Gen 1)

With an outer diameter (OD) at 0.510”, Omnetics designed this offering with SWaP in mind. Using both simulation and measurement, Omnetics maximized the performance for USB 3.0/USB 3.1 (Gen 1) within the connector design. Micro contacts are used to provide maximum current rating for the power pins; meanwhile, Nano contacts are used for the high-speed data lines. This solution is spaced at precise locations in order to ensure maximum data transfer.

As speeds increase beyond 1 Gbps, the cable becomes as important – or more important – to the performance as the connector. USB 3.0 introduced new requirements that significantly stress the capabilities of nearly every cable manufacturer. The cable must maintain an impedance of 90Ω±7Ω, all the while providing intra-pair skew of less than 15ps/m.

Omnetics’ USB 3.0 Circular product provides maximum data transmission and excellent crosstalk that meets the requirements of USB 3.0/USB 3.1 Gen 1. Available overmolded for an IP68 seal, this connector family is available both in-line as well as mountable in (3) panel mount configurations (Front, Rear, Protruding).

Ruggedized Nano 360® HDMI

Falling in line with the USB 3.0 offering, Omnetics Nano HDMI circular fits all nineteen signal pins into an OD of only 0.550”. This new connector configuration is designed to meet HDMI 2.0 specifications. Using both simulation and measurement, performance was maximized through a carefully designed signal pinout to meet an impedance of 100Ω through the connector.

The HDMI cable includes the same challenges at the USB 3.0 cable, but with a wire count of nineteen instead of nine. With nineteen wires, achieving miniaturization while maintaining flexibility is a challenge. There is always a tradeoff between performance and size, but it is much more pronounced for this product. In order to achieve the best balance, 32 AWG cable is used. This limits the maximum overall length, but measurements confirm that the specification can be met up to about 3-meters.

The final product results in excellent crosstalk, impedance, and maximum data transmission in order to meet the requirements of HDMI 2.0 specification.

Ruggedized Nano 360® Cat6a & Micro 360® Cat6a

This particular offering allows designers (2) sizes to choose from: Micro 360® (0.600” OD) or Nano 360® (0.460” OD). Similar to USB 3.0 and HDMI, crosstalk and impedance are important parameters to optimize. Contrary to USB and HDMI, crosstalk is more critical than impedance here. In this connector design, these two parameters are inversely proportional: increasing the pin-to-pin spacing within a pair improves the impedance but degrades the crosstalk. As with all high-speed designs, there are trade-offs that need to be made, and both simulation and measurement help determine the optimal configuration. The end result is a novel 5-pin grounding strategy that optimizes the performance and meets the requirements of Cat6a, per TIA-568-C.2.

The cable must be designed to meet the Cat6a requirements. Fortunately, the requirements provide a little more margin for miniaturization: TIA-568-C.2 allows for up to 100 meters in cable length with a standard (22-24 AWG) cable. A smaller cable will have more loss, but even at 30 AWG, can still meet the performance requirements up to at least 25 meters. This is significantly longer than nearly all Omnetics jumpers, so it’s rarely an issue. Cables are available both in military grade (polyurethane jacket) and aerospace grade (Teflon jacket).

Latching Micro-D and Nano-D Connectors

Latching Micro-D and Nano-D connectors from Omnetics employ a squeeze-latch system that offers significant advantages in making quick cable connections to mating connectors and panel equipment. In addition to being very small and lightweight, our latching connectors are available at both 25 and 50 mils. (one thousands of an inch) spacing.

Latching Micro-D and Nano-D connectors from Omnetics employ a squeeze-latch system that offers significant advantages in making quick cable connections to mating connectors and panel equipment. In addition to being very small and lightweight, our latching connectors are available at both 25 and 50 mils. (one thousands of an inch) spacing.

They have passed extensive  shock and vibration testing, including pull testing that exceeds 100 pounds of pull force. The new push-and-latch design significantly reduces the time and effort required to plug a Micro-D or Nano-D connector into a circuit. It eliminates the use of screwdrivers and hand tools.

shock and vibration testing, including pull testing that exceeds 100 pounds of pull force. The new push-and-latch design significantly reduces the time and effort required to plug a Micro-D or Nano-D connector into a circuit. It eliminates the use of screwdrivers and hand tools.

Applications we have served include portable electronic modules and instruments used in a wide range of rugged applications. Unmanned vehicles, optical surveillance, and flight deck test equipment require quick connect and disconnect methods not readily available before in a rectangular-shaped connection systems. Medical devices, such as surgery tools, ultrasound monitors, and imaging scopes require frequent connection and removal from instrument panels.

Panel-mounted latching connectors offer options for connecting front panels to inside instrumentation, including P.C. board lead frames and direct wiring. These highly rugged connectors with their compact designs are built with aluminum alloy 6061 shells plated with nickel (other materials are available). Contact counts range from 9 to 51 positions.

Panel-mounted latching connectors offer options for connecting front panels to inside instrumentation, including P.C. board lead frames and direct wiring. These highly rugged connectors with their compact designs are built with aluminum alloy 6061 shells plated with nickel (other materials are available). Contact counts range from 9 to 51 positions.

The connectors use a one-piece beryllium copper flex pin design, plated with nickel/gold for robust service that operates from -55 degrees to +125 degrees C. Wired connectors include 26 AWG Teflon® insulated copper wire that provides up to 3 amps per line on Micro sizes and offer 30 and 32 AWG wiring for the Nano sized connectors. A wide range of wire count and cables can be designed into custom back-shells for long-range ruggedized service. Cable systems include braided shields to reduce electromagnetic interference (EMI) and cross talk.

beryllium copper flex pin design, plated with nickel/gold for robust service that operates from -55 degrees to +125 degrees C. Wired connectors include 26 AWG Teflon® insulated copper wire that provides up to 3 amps per line on Micro sizes and offer 30 and 32 AWG wiring for the Nano sized connectors. A wide range of wire count and cables can be designed into custom back-shells for long-range ruggedized service. Cable systems include braided shields to reduce electromagnetic interference (EMI) and cross talk.

Digital signals, such as the HDMI Nano-latch connector shown, optical surveillance systems, and low-voltage differential signals are applying these quick-change connectors in their systems. The latching Micro-D and Nano-D family has years of solid reliable experience in the field and has saved a lot of connection and disconnection time.

Relocation of Precision Machining Division

Omnetics is expanding! Our Precision Machining Division has relocated to a facility in Blaine, Minnesota. The new facility will expand the space from approximately 1,500 square feet to over 12,000 square feet. The expanded Precision Machining Division will help us continue to serve our customers and grow our business.

From the Engineer’s Desk: High Speed Connector Design

What is Coax?

by Ryan Satrom, Signal Integrity Engineer

The coax connector industry is worth over $2 billion per year (Connector Supplier). They are used in communication devices, wireless applications, satellites, audio, and video. Nearly all markets utilize coax connectors, from military to medical to aerospace. There are similarities to other connector styles, but there are also aspects that set coax connectors apart. This is the first in a series of articles that are aimed at helping readers better understand coax connectors – what they are, why they are used, and current offerings from Omnetics.

Figure 1. Layers of a coax cable.

Coax, short for co-axial, literally means “joint/mutual axis”. In the case of coax connectors, there are typically four layers that all share the same axis and center point.

- Signal: Typically a solid wire, though stranded wire can be used for certain applications.

- Insulator: A material with a low dielectric constant (εR) that allows for high-frequency signal transmission.

- Shield: The shield has two primary purposes: (1) carry the ground currents for the coax signal, and (2) block all signals from the outside world. The shield generally consists of a foil, a braid, or both. It is designed with 100% coverage so that the coax signal is fully isolated. This can be achieved due to what is called “skin effect”.

- Jacket: Provides protection for the cable.

Figure 2. Current distribution of a coax signal at high frequency.

Skin effect is a phenomenon that describes how signals travel at high frequency where they will seek not only the path of least resistance but also the path of least inductance. As frequencies increase, current distribution (Figure 2, red) will both move further to the outside of the conductor and move as close as possible to the opposite-travelling current. This pushes all currents on the shield to the inside portion of the shield, ensuring that no current exists on the outside of the shield, and thus no signal will radiate to create EMI.

The co-axial construction is designed to better address the following two needs of high-frequency signals:

- Characteristic Impedance: As frequencies increase, the characteristic impedance of the coax becomes critical. The impedance is determined primarily by the diameter of the signal conductor, the OD of the insulator, and the dielectric constant of the insulation material.

- Excellent Shielding: The outer shield fully surrounds the signal conductor, yielding nearly perfect coverage.

In future articles, we will look in-depth at coax, including impedance, the purpose of coax contacts, and their strengths and weaknesses. These articles will provide a deeper understanding of the uses for coax and will assist engineers in selecting the correct coax connector with confidence. A description of the coax offerings at Omnetics will be included.

Did you know?

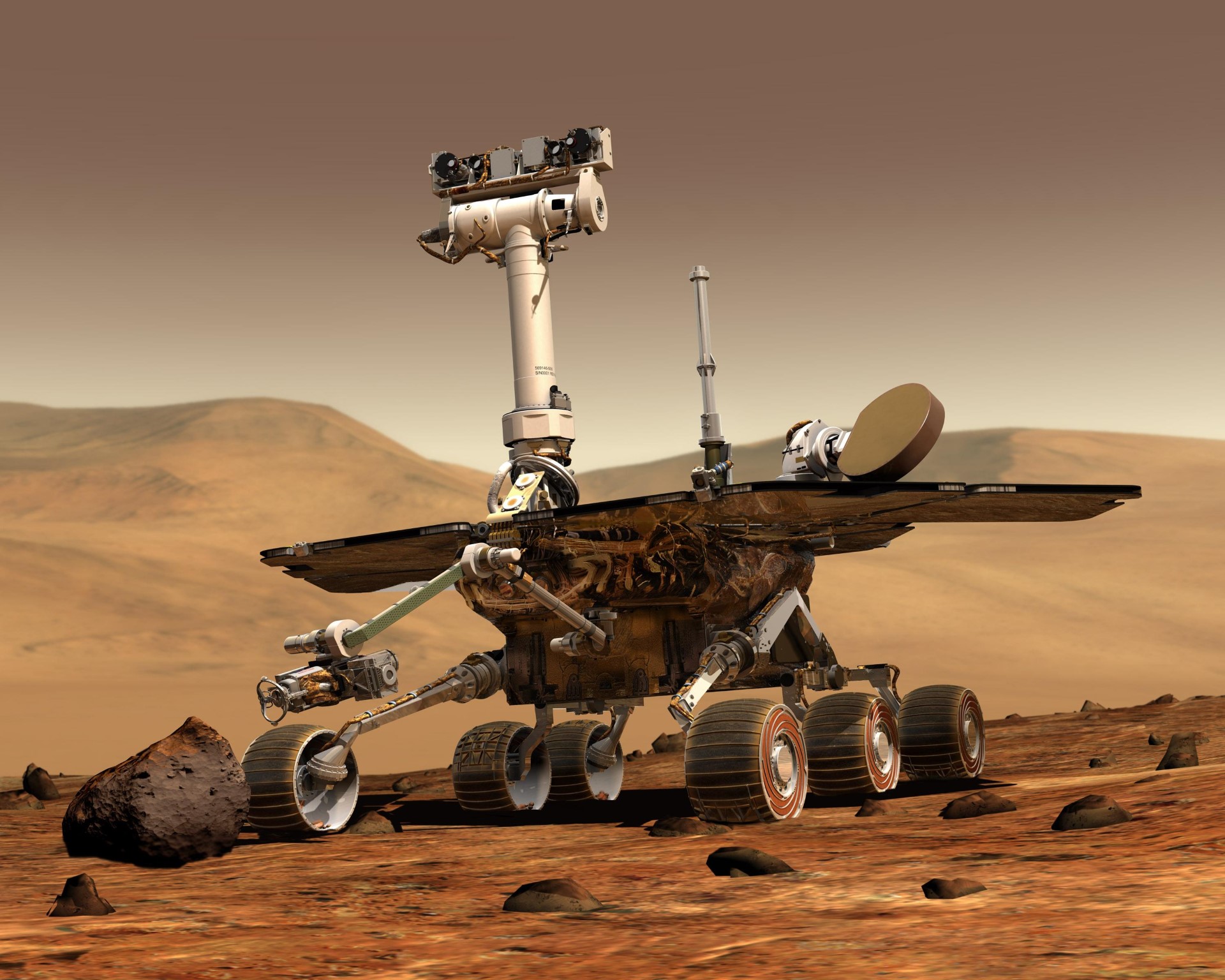

NASA’s Opportunity rover has  officially been on Mars for 15 years! It was designed to operate for 90 Martian days, but completed over 5,000 Martian days on the red planet as of February 2018. Although NASA is currently unable to communicate with Opportunity due to a dust storm in June, Opportunity has given NASA the chance to expand their discovery of space and Mars.(NASA)

officially been on Mars for 15 years! It was designed to operate for 90 Martian days, but completed over 5,000 Martian days on the red planet as of February 2018. Although NASA is currently unable to communicate with Opportunity due to a dust storm in June, Opportunity has given NASA the chance to expand their discovery of space and Mars.(NASA)

Omnetics’ Nano connectors are used on space missions for their small size and extreme durability. More information on our connectors for space is available.

Calendar of Events

5-7

SmallSat Symposium

Location: Mountain View, CA

17-21

IDEX

Location: Abu Dhabi, UAE| Stand FT-006

11-13

Future Soldier Technology

Location: London, United Kingdom

30-2

AUVSI Xponential

Location: Chicago, IL, USA | Booth #3639

6-8

Navy Sea Air Space

Location: National Harbor, MD, USA | Booth #1251

20-23

SOFIC

Location: Tampa, FL, USA | Booth #1343