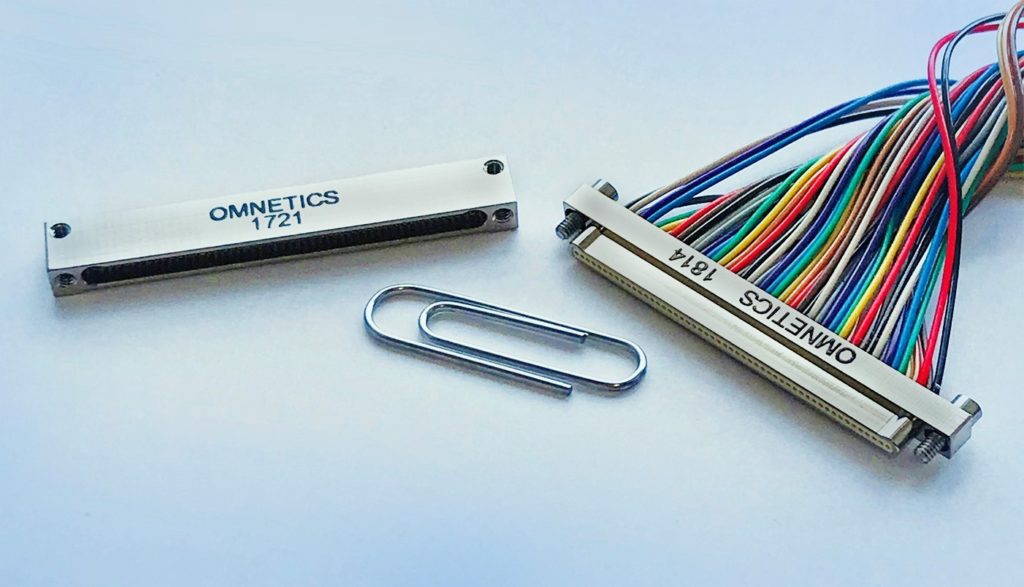

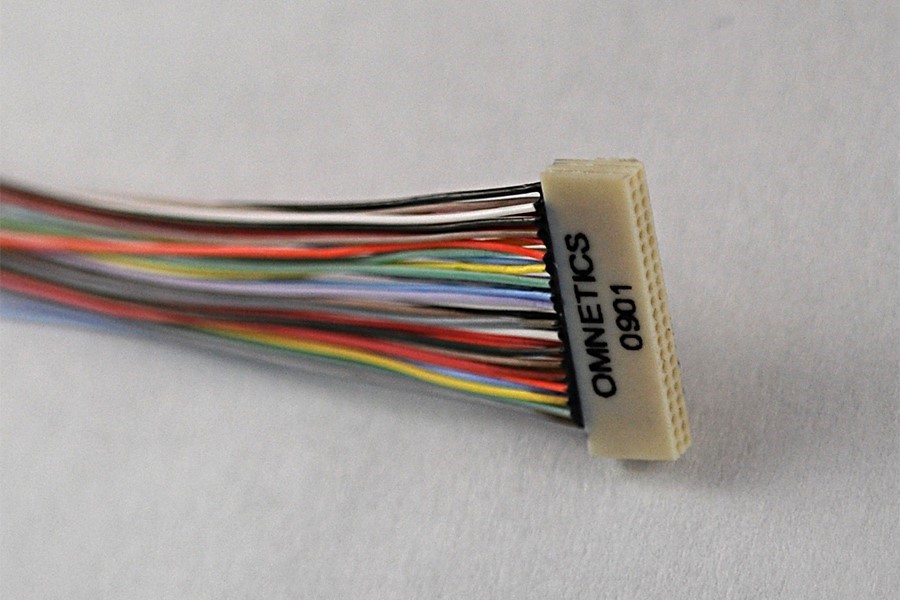

Omnetics Connector Corporation has begun a dual qualification for our connector marking systems. For many years, Omnetics has been using a two part epoxy ink system which has met all associated military durability and NASA outgassing requirements. This system has been used successfully on all Omnetics product families including both metal and plastic housings. Due to an increase in customer requirements for additional marking criteria including part number revision level and serial number marking, Omnetics has added a Videojet V548 marking system to our capabilities. This new system has been qualified through a vigorous independent laboratory testing program.

The system has been tested to and met the requirements of the following specifications using multiple finishes and materials:

- Resistance to Solvents: MIL-STD-883L, Method 2015.14

- Resistance to Solvents: MIL-STD-202H, Method 215 with Change 1

- Outgas Test: ASTM E595, paragraph 1.5

These test reports are available upon request. Omnetics will actively reach out to existing customers who have specified our two part epoxy ink system on their drawings and will notify them regarding this alternate marking method. This announcement will act as a general notification to all our customers that Omnetics may use either approved method of marking for their product. Omnetics continues to work hard to maintain the highest levels of quality for all of our manufacturing systems and products. If you have any questions regarding this announcement, please contact our technical staff for additional information.