Engineering

For almost 40 years, Omnetics Engineering team has been bringing innovation to the connector industry and is now partnering with our customers to facilitate the integration of miniature electronic connectors into a variety of closely spaced environments. Omnetics uses a three pronged approach for the development of custom connectors

Manufacturing

All of our products are manufactured in our Minnesota factory in compliance with ISO 9001 and AS9100 quality standards. Our employees understand the importance of quality throughout every aspect of a connector build. Whether you are looking for a simple board mount connector or a complicated Source Control Drawing harness, we work closely with you to make sure we understand all of your requirements up front.

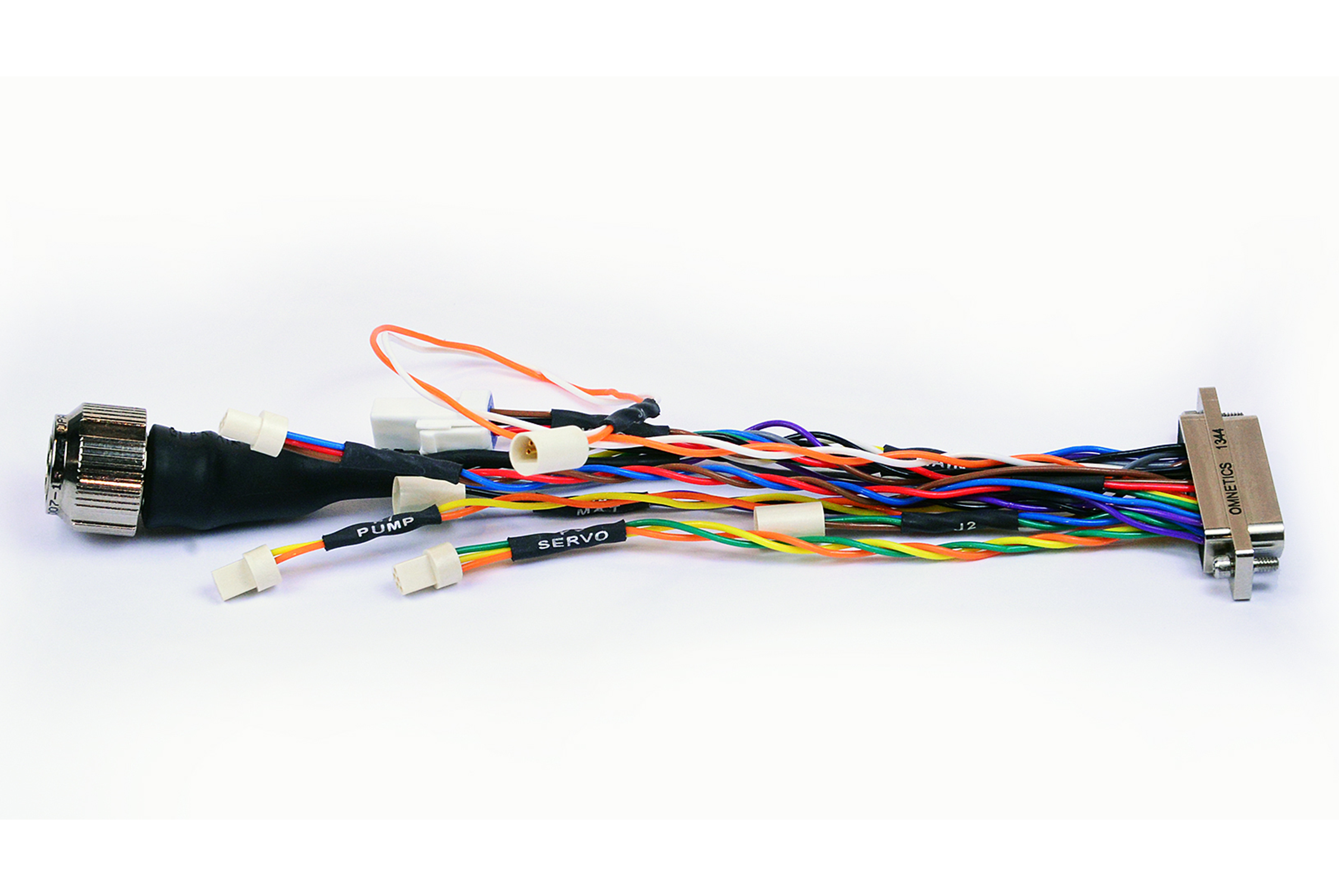

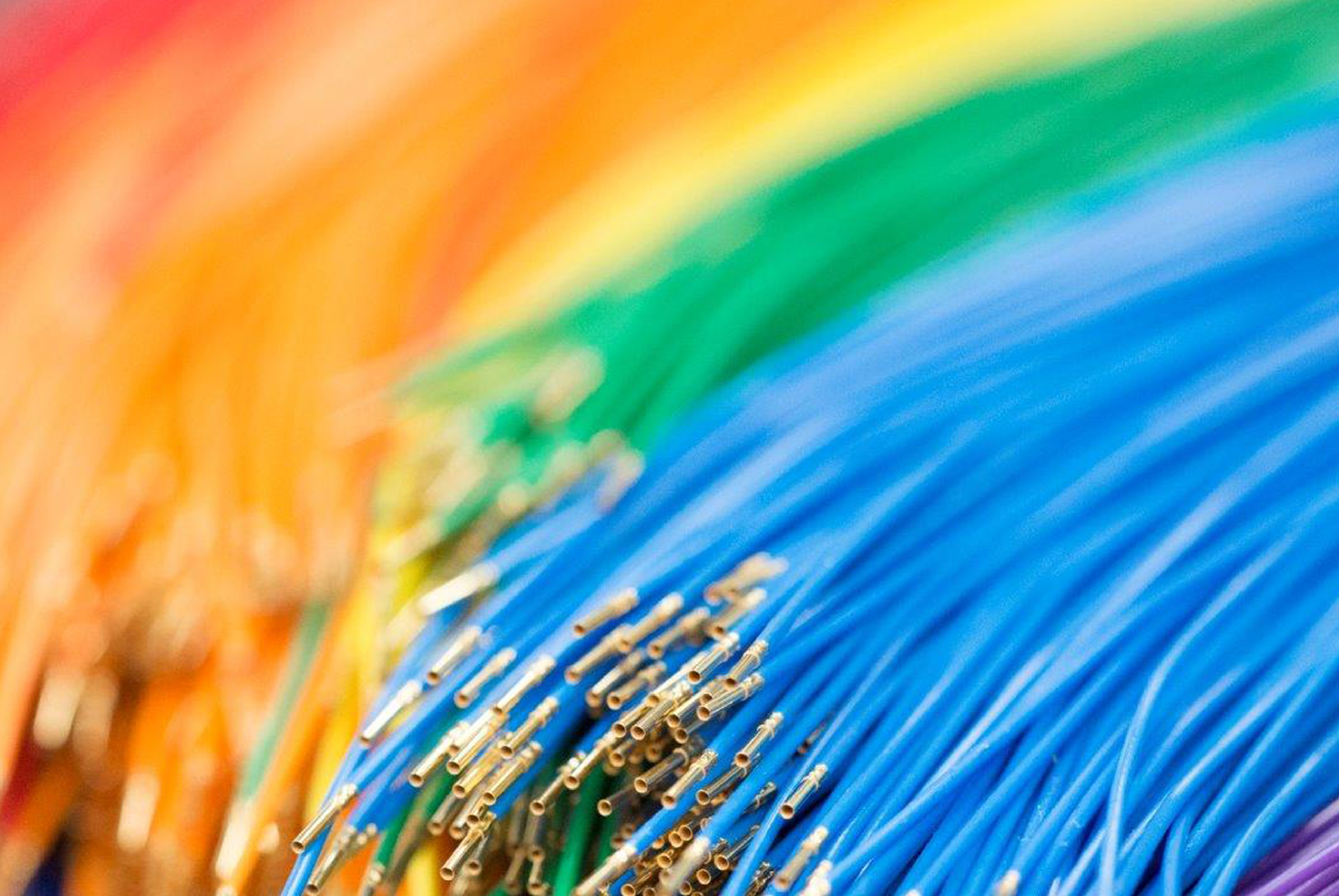

Cable Assembly

Omnetics specializes in miniature connectors and small wire gauge interconnects and is well suited to meet the cable harness needs of our customers, with IPC-610 and IPC-620 trained workers on-site.Omnetics specializes in application-specific connector to cable systems. Our expert designers have experience designing harnesses for complex and harsh environment applications. Omnetics designers have the necessary experience needed to meet the Quality and Performance specifications required by the US Military, NASA and ESA.

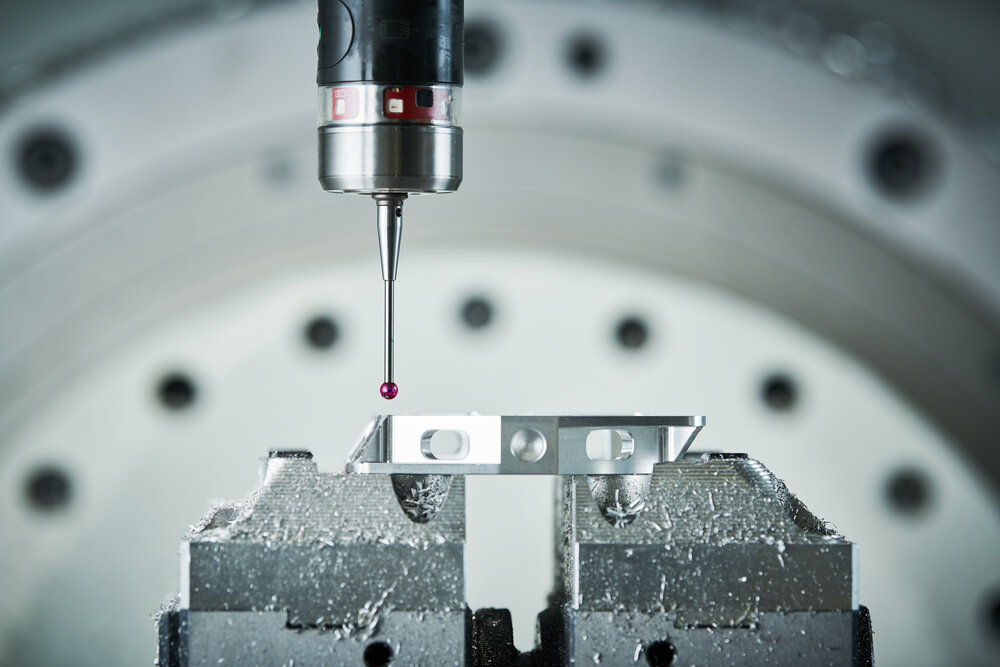

Precision Machining Division

Precision is our specialty. Focused on customer service, precise machining, reliable quality, and committed to on-time delivery.

Injection Molding

Omnetics Connector Corporation offers extensive overmolding design and manufacturing capabilities. The typical case is for Omnetics to provide an overmold for our own standard or custom-designed connector, and value-added molds such as strain reliefs, grommets, and yokes. Our expertise consists of working with customers in the medical, defense, aerospace, electronics, and other industries that require complex needs.

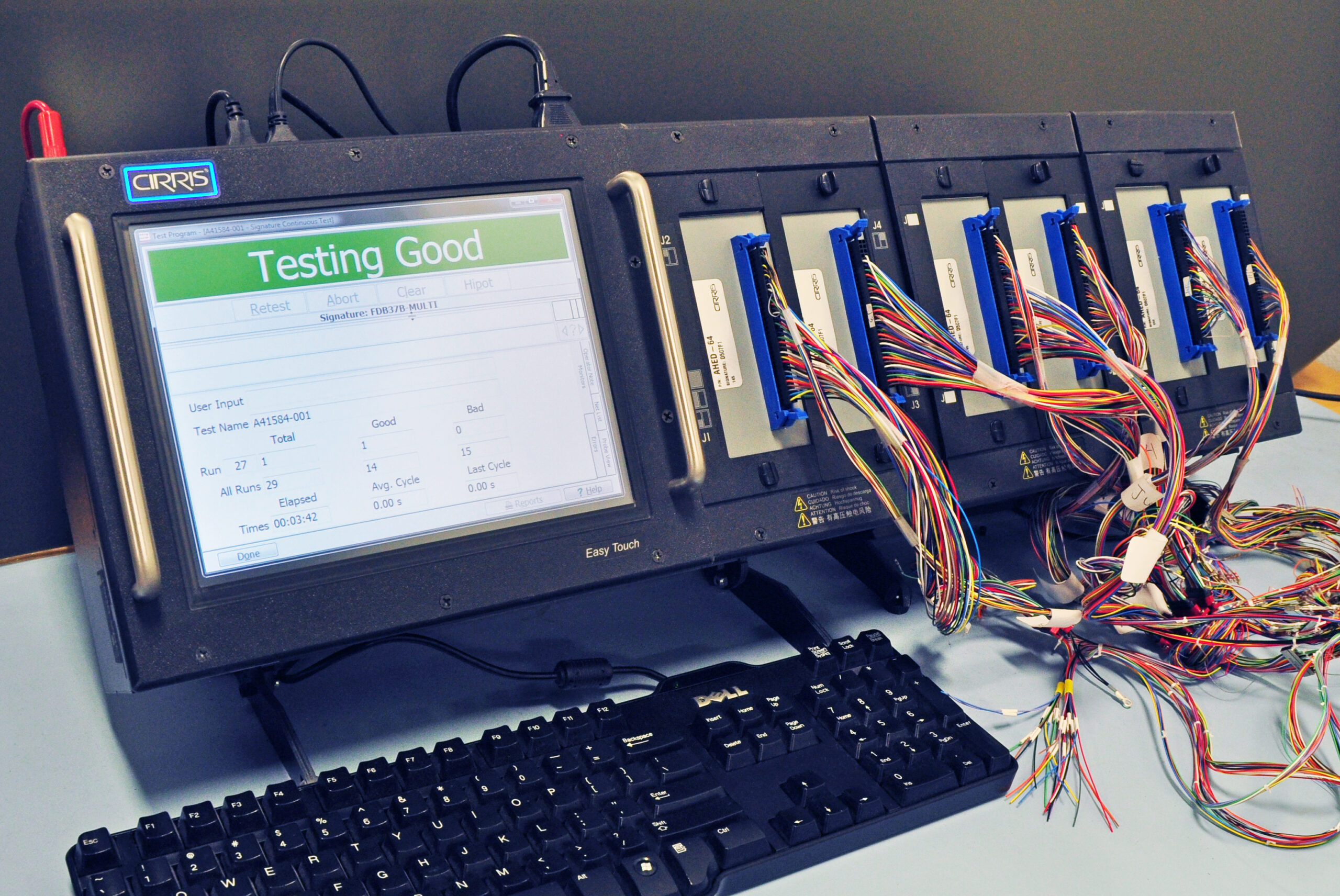

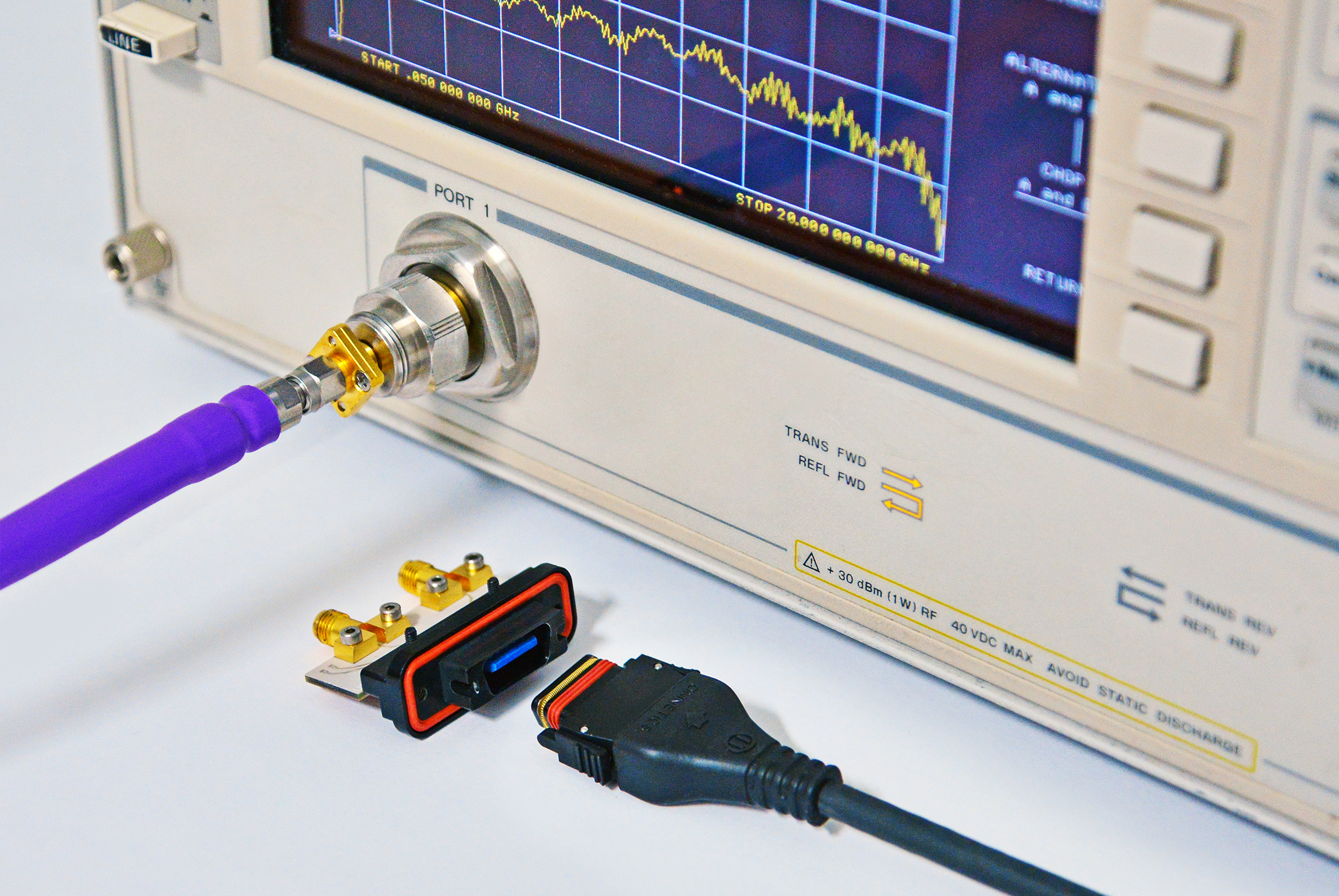

Test Capabilities

Material Selection & Finishing

Precision is our specialty. Focused on customer service, precise machining, reliable quality, and committed to on-time delivery.

Special Projects Laboratory

Omnetics Special Projects laboratory is a design engineers dream. A cell within our manufacturing floor, with the main objective of providing quick turn prototyping services and product samples for designers looking to implement Omnetics products during early stages of product development.

Signal Integrity R&D and Support

High reliability connectors will always be a cornerstone for Omnetics, but for many applications, a robust mechanical design must be balanced with a solution that is also optimized for high-speed.