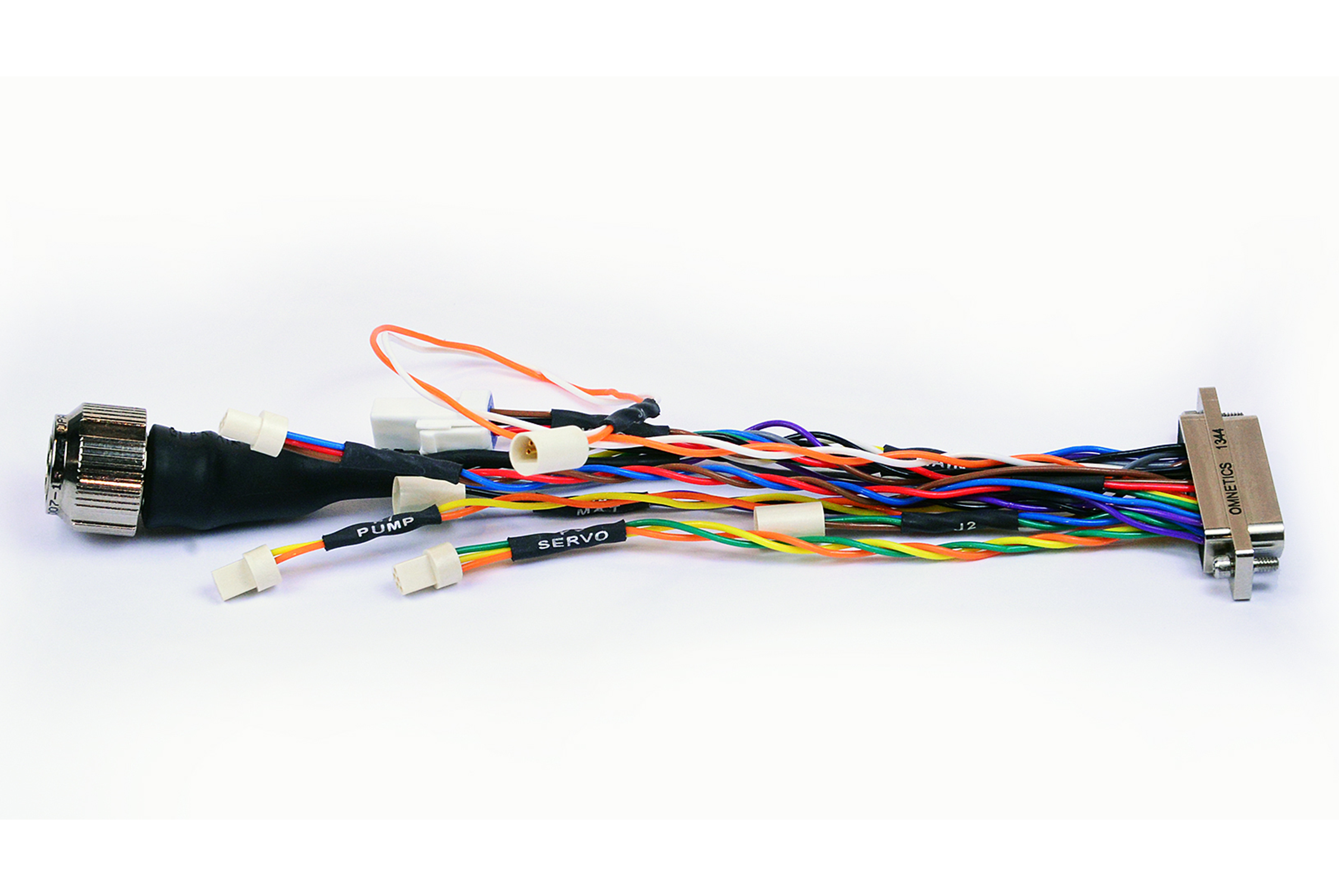

Cable Assembly

We design and manufacture a wide range of custom cable solutions to support all of our various product lines, while allowing your team to guide the design.

To minimize the design cycle time, Omnetics utilizes engineer-to-engineer communications. Omnetics will be available to assist your team from the developmental stages, to prototyping all the way through production. Omnetics’ Design Engineering Team uses SolidWorks. Omnetics does not typically charge for our engineering services which allows our customers to explore solutions to their interconnect challenges without having to generate Pos or go through lengthy approval processes. We are able to offer step files, printed prototypes and drawings prior to finalizing the design. This minimizes customer risk and results in successful implementation for prototype and production assemblies.

Omnetics Connector Corporation follows IPC/WHMA-A-620 for all cable assembly, test and inspection practices. Omnetics Cable Harness Brochure (2023)

Custom Cable Assemblies Options |

Cable Assembly Processing Capabilities |

Testing |

|

|

|