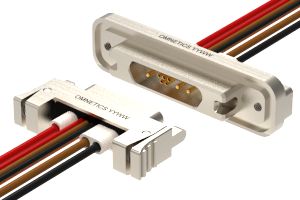

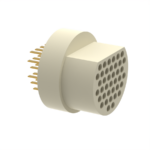

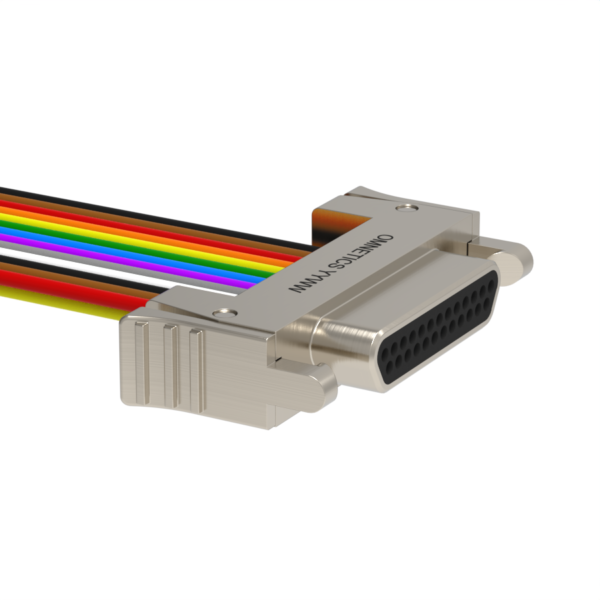

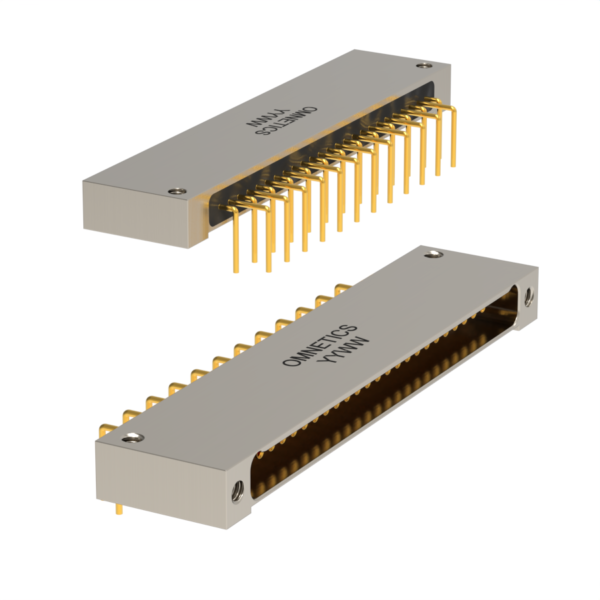

Latching Power Micro-D

$1.00

Omnetics high reliability Micro-D connectors are available with mixed power/signal contact layouts.

Resources

| Title | Type | File |

| Latching Power Micro-D Contact | Download | |

| Latching Power Micro-D Ordering Guide | Download | |

| Latching Power Micro-D Hardware & Misc. | Download |

Description

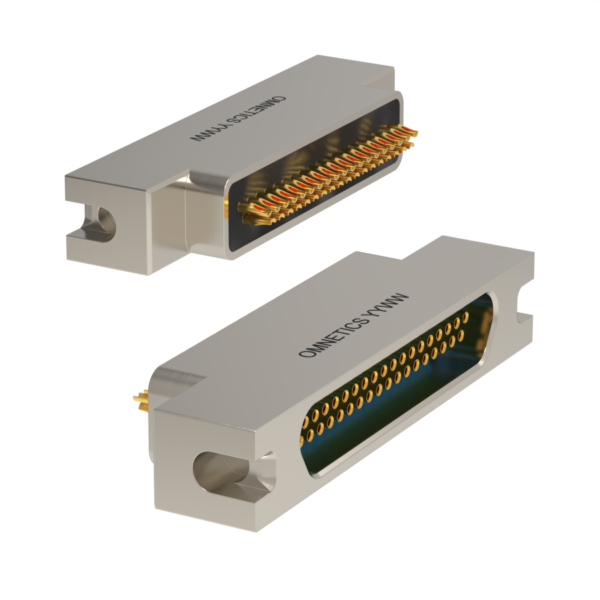

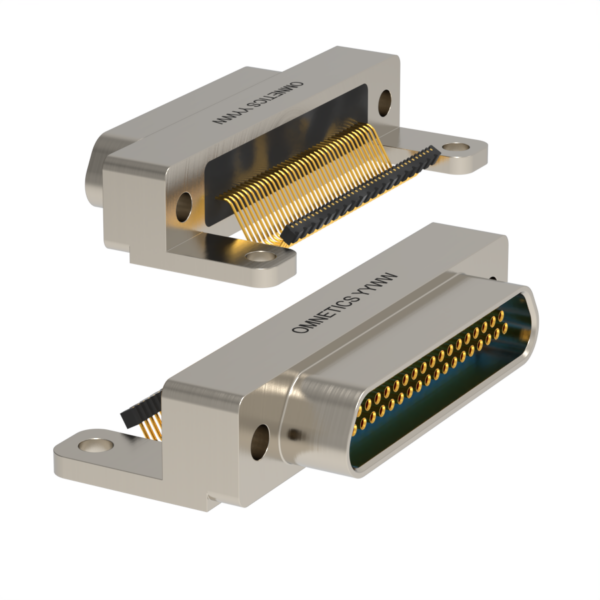

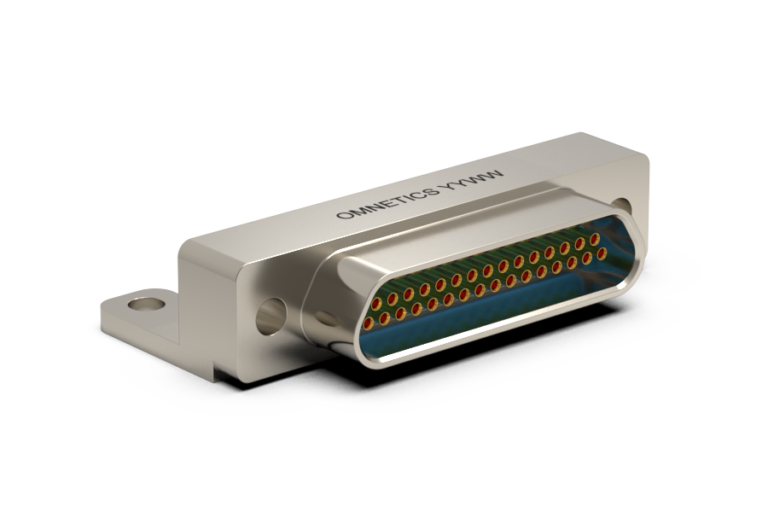

Omnetics high reliability Micro-D connectors are available with mixed power/signal contact layouts. The number of power and signal contacts may be specified to provide the greatest flexibility in circuit design while ensuring that the connector is kept to the absolute minimum necessary size. This hybrid combination eliminates the need to have a d-sub type or other higher power connector next to the micro-d and making it easier for the operator who now only needs to mate a single connector. The power contact can handle 20-24 AWG wire and is suitable for use up to 10 Amps. These hybrid connectors are available in wired or thru hole PCB mount termination types. The wired power contact is an insertable/removable type contact which can be optionally supplied for customer termination.

Additional information

| Omnetics Series |

LMDP ,LMDS |

|---|---|

| Number of Contacts (Power) |

15 ,21 ,25 ,31 ,37 ,51 ,9 |

| Rows |

2 Rows |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Latch |

Stainless Steel, Nickel Plated |

| Latch Spring |

Stainless Steel |

| Retaining Pin |

Stainless Steel |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |

Features

Omnetics’ Latching Micro-D connectors offer a rugged quick latch system. The Latching Micro-D connectors are availbale in sizes 9-51 and use Omnetics’ Flex Pin contact system, which meets all the standard performance requirements of MIL-DTL-83513, including shock and vibration. These connectors provide a secure connection without the need for tools and jacking hardware and are available in wired, board mount, panel mount configurations as well as with back shell options.

Specifications

| Omnetics Series |

LMDP ,LMDS |

|---|---|

| Number of Contacts (Power) |

15 ,21 ,25 ,31 ,37 ,51 ,9 |

| Rows |

2 Rows |

| Electrical Mechanical Specifications |

– |

| Temperature |

-55ºC to +125ºC (200 ºC w/HTE) |

| Dielectric Withstand Voltage |

600 VAC RMS at Sea Level |

| Contact Resistance |

26 milliohms max (65 mV drop) @ 2.5 AMPS |

| Current Rating |

3 AMPS per contact |

| Durability |

2\,000 Mating Cycles min |

| Insulation Resistance |

5000 Meg ohms @ 500 VDC |

| Shock |

50 gs with no discontinuities > 1 microsecond |

| Vibration |

20 gs with no discontinuities > 1 microsecond |

| Thermal Vacuum Outgassing |

1.0% max TML\, 0.03% CVCM – NASA SP-R-0022 |

| Mating/Unmating Force |

3 oz (85 g) typical per contact |

| Material Specifications |

– |

| Contact |

Copper Alloy per MIL-DTL-83513 |

| Contact Finish |

Gold per ASTM B488\, Type II\, Class 1.27\, Code C Over Nickel Underplate |

| Insulator |

Thermoplastic per MIL-DTL-83513 |

| Interfacial Seal |

Fluorosilicone Elastomer per A-A-59588 |

| Hardware |

Stainless Steel\, 300 Series\, Passivated per SAE AMS-2700 |

| Latch |

Stainless Steel, Nickel Plated |

| Latch Spring |

Stainless Steel |

| Retaining Pin |

Stainless Steel |

| Shell Options |

– |

| Aluminum Shell, Electroless Nickel Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8 or ASTMB221 Nickel per SAE AMS-2404 |

| Aluminum Shell, Cadmium Plated |

Alloy 6061 per SAE AMS-QQ-A-200/8\, Cadmium with Yellow Chromate Conversion per SAE-AMS-QQ-P-416\, Type II\, Class 3 Over Nickel Underplate |